Table of Contents

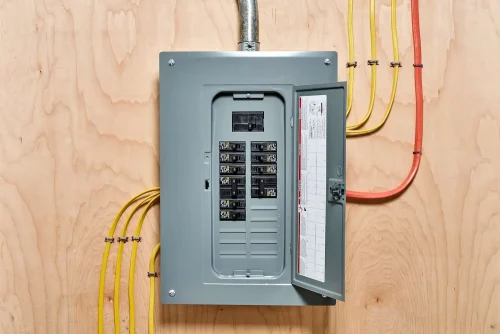

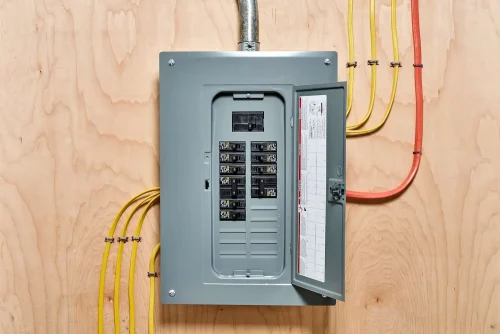

A power distribution box plays a vital role in any electrical system. It receives electricity from the main supply and distributes it safely to various circuits within homes, offices, or industrial facilities. Without this device, handling electricity would be chaotic, risky, and inefficient.

This guide will cover what a power distribution box is, its working principle, and its significance. Whether you’re a homeowner, an electrician, or simply interested, this article will provide a straightforward and easy-to-understand explanation.

What Is a Power Distribution Box?

A power distribution box is an essential component of any electrical system. It takes electricity from the main source and splits it into different circuits. Depending on the context, it may also be known as a PDU (Power Distribution Unit), distro, or distribution panel.

Think of it as the central hub of your electrical setup. Instead of delivering power straight to each device, it manages and regulates the flow. This organization helps keep the system safer and more manageable.

How Does a Power Distribution Box Work?

A power distribution box acts like a traffic controller for electricity. It receives power from the main supply and routes it to different devices or areas through separate circuits. This keeps your electrical system organized and running smoothly.

Here’s a simple breakdown of its operation:

- Electricity enters the box from the main power line.

- Inside, the power splits into multiple circuits, each supplying a specific area, such as a kitchen, workshop, or machinery.

- Safety devices like circuit breakers or fuses monitor the current. If an overload or short circuit occurs, they automatically shut off the affected circuit to prevent damage.

- Bus bars and internal wiring distribute electricity efficiently to each circuit.

- The box balances the electrical load to ensure no wire or device receives too much power.

These safety measures keep your equipment, space, and peace of mind protected.

Key Components of a Power Distribution Box

Inside a power distribution box, several components work together to control, manage, and protect the electrical system. Here are the main parts and their functions:

- Circuit Breakers (MCBs): These act as automatic protectors. When too much current flows through a circuit, the breaker trips to cut the power, preventing damage or fire.

- Fuses: Like breakers, fuses guard against overcurrent but melt when triggered and need to be replaced.

- Surge Protection Devices (SPDs): These protect your appliances from sudden voltage spikes caused by events like lightning or grid surges.

- Residual Current Devices (RCDs/RCBs): These enhance safety by shutting off power if they detect electricity leaking, for example, through a person.

- Main Switch: This serves as the central control to turn off or on the entire system, useful for emergencies or maintenance.

- Bus Bars and Internal Wiring: These act as internal pathways, carrying power from the input to each circuit, ensuring smooth and efficient distribution.

- Optional Add-ons: Some advanced boxes may include digital monitoring systems to track energy use, spot faults, or enable remote management.

All these components work in harmony to keep your power system safe, reliable, and easy to control.

Types of Power Distribution Boxes

Not all power distribution boxes are alike. Different situations require different types, based on space, power needs, and control levels. Here are some common types you’ll encounter:

- Main Circuit Breaker Panels:This is the central control point for most electrical systems. It connects directly to the main power supply and distributes electricity to all primary circuits. It usually includes a large breaker that can shut off the entire system when necessary.

- Sub-Panels:These act as secondary distribution boxes to extend the capacity of the main panel. They are commonly used in garages, workshops, or other areas that need separate circuit control without running new wiring from the main panel.

- Main Lug Panels:Similar to sub-panels but without a main breaker. Instead, they depend on a main breaker located upstream. These are useful for system expansions when space or budget is limited.

- Fuse Boxes:An older type of distribution box that uses fuses instead of breakers for circuit protection. Although less common in new constructions, they still exist in some older homes. They offer less flexibility and fewer safety features compared to breaker panels.

- Transfer Switches:Important in systems with backup power like generators. They allow safe switching between the main grid and backup power, preventing overload or backfeed.

- Smart Power Distribution Boxes (Smart PDBs):Modern versions equipped with IoT features such as energy monitoring, fault alerts, and remote control. Ideal for advanced facilities, data centers, or users who want real-time power usage tracking.

| Type | Description | Typical Use |

|---|---|---|

| Main Circuit Breaker Panels | Primary control center, connects to main power, includes main breaker | Most electrical systems |

| Sub-Panels | Secondary box to extend main panel capacity, controls specific areas | Garages, workshops, separate zones |

| Main Lug Panels | No main breaker, relies on upstream breaker, suitable for budget or space-limited expansions | System expansions |

| Fuse Boxes | Older style using fuses instead of breakers, less flexible and safe | Older homes |

| Transfer Switches | Allows safe switching between main and backup power sources | Backup power systems with generators |

| Smart Power Distribution Boxes (Smart PDBs) | IoT-enabled with energy monitoring, fault alerts, remote control | Advanced facilities, data centers, real-time power monitoring |

Choosing the right type depends on your specific project, power requirements, and safety needs. Each type serves a unique purpose but all ensure your electricity flows smoothly and safely.

Where Power Distribution Boxes Are Used

Power distribution boxes are essential in many settings, from homes to hospitals. Here’s a look at some common uses:

Residential Applications

In homes, these boxes manage daily power needs. They control electricity for kitchen appliances, lighting, HVAC systems, and bathroom outlets. By splitting power across different circuits, they improve safety and help prevent overloads.

Commercial Buildings

Offices, malls, and restaurants depend on distribution boxes to handle larger electrical demands. Separate circuits for air conditioning, IT equipment, lighting, and kitchens provide better control and ensure reliable power in busy areas.

Industrial Facilities

Factories, warehouses, and data centers need strong power systems. Distribution boxes here are designed to support high voltages, heavy machinery, and critical operations. They often include special safety features for constant, around-the-clock use.

Events and Entertainment

Concerts, exhibitions, film sets, and festivals require quick, adaptable power setups. Portable power distribution units safely supply stage lighting, sound systems, and vendor booths while keeping everything organized.

Critical and Off-Grid Systems

Hospitals, telecom centers, and remote solar installations rely on steady power. Distribution boxes in these locations often work with backup generators or renewable energy sources to ensure uninterrupted service to vital systems.

Benefits of Using a Power Distribution Box

A power distribution box keeps your electrical system safe and efficient. Here are its main advantages:

Improved Safety

It protects against overloads, short circuits, and electrical fires by using circuit breakers and fuses to cut power when issues arise. This safeguards both your equipment and everyone around.

Efficient Power Distribution

The box ensures power is shared evenly across circuits, preventing any single line from becoming overloaded. This helps the system run better and saves energy.

Easy Control

Having all circuits in one place makes managing power simple. You can switch off power to a specific area without shutting down the whole system.

Expandable for Growth

Many distribution boxes are modular, allowing you to add more circuits as needed. This flexibility is ideal for growing homes, businesses, or events.

In short, a power distribution box makes your power setup safer, more efficient, and easier to manage.

Materials and Standards to Look For

Selecting a power distribution box involves more than just its internal parts—it also depends on the materials used and the certifications it holds. These factors impact safety, durability, and performance.

Durable and Safe Materials

Choose boxes made from flame-retardant, corrosion-resistant, and impact-resistant materials. These qualities protect against fire, moisture, and physical harm, especially in harsh environments like factories or outdoor locations.

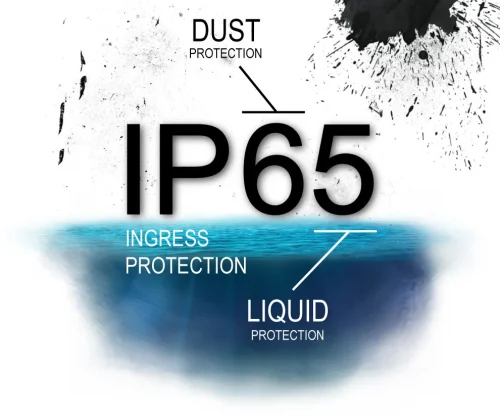

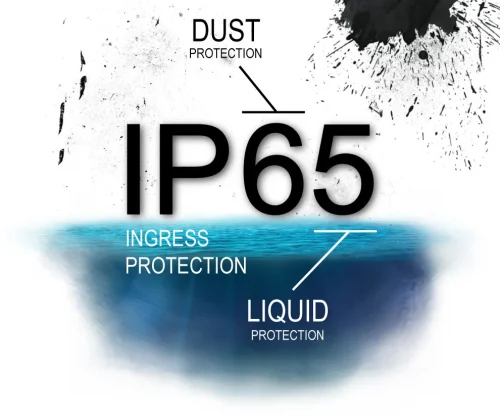

IP Rating for Outdoor Use

If the box will be exposed to dust, water, or outdoor conditions, check its IP rating. This rating shows how well the box is sealed against dust and moisture. For instance, an IP65 rating means the box is tightly sealed and can handle splashes or light rain—ideal for outdoor use.

Essential Safety Standards

Ensure the box carries important certifications such as:

- UL (Underwriters Laboratories): A U.S. safety standard confirming the box has been tested for electrical and fire hazards.

- IEC (International Electrotechnical Commission): Global standards that guarantee electrical safety and quality.

- CE (Conformité Européenne): Required for products sold in Europe, indicating compliance with EU health and safety rules.

- RoHS (Restriction of Hazardous Substances): Certifies the box is made without harmful substances like lead or mercury.

Choosing a box with these materials and certifications means you’re getting a product that’s reliable, safe, and built to endure.

How to Choose the Right Power Distribution Box

Picking the right power distribution box may seem challenging, but it’s simpler when you focus on a few key factors. This will help you get a safe, efficient setup that meets your needs now and in the future.

Understand Your Power Requirements

Begin by calculating your load capacity—the total power your system will use—and how many circuits you need. A small home requires fewer circuits, while a large factory or office needs many more. Choosing the correct size from the start helps avoid future issues.

Select Proper Protection Devices

Ensure the box includes vital safety features like Miniature Circuit Breakers (MCBs) to prevent overloads, Residual Current Devices (RCDs) to guard against electric shocks, and Surge Protection Devices (SPDs) to protect from voltage spikes. These devices protect your equipment and enhance safety.

Plan for Size and Future Expansion

Your box should comfortably fit your current wiring but also allow for growth. If you expect to add circuits or equipment later, choose a scalable, future-ready box. Having extra space now can save time and money later.

Consider the Installation Environment

Think about where the box will be placed. Standard boxes work well indoors, but for outdoor or harsh conditions, select one with a high IP rating, strong materials, and weather-resistant features.

Installation and Maintenance Tips

Proper installation and care of a power distribution box are essential to keep your system safe and running smoothly. Here’s what you need to know:

Have a Professional Handle Installation

Always hire a licensed electrician to install your box. They will ensure all wiring is done correctly and safely. Poor installation can lead to short circuits, overheating, or even fires, so it’s best to avoid risks.

Typical Installation Steps

The process usually involves:

- Mounting the box securely in a well-ventilated area.

- Connecting the main power supply to the input terminal.

- Wiring individual circuits to match your building’s layout.

- Testing each circuit and safety device to ensure everything functions properly.

A neat and organized setup also makes future maintenance easier.

Maintenance Checklist

To keep your box in good condition:

- Inspect it regularly for wear, rust, or signs of overheating.

- Look for loose connections or tripped breakers.

- Test safety devices like RCDs and SPDs.

- Replace any damaged parts, especially circuit breakers or fuses, immediately.

Performing these checks every few months can prevent major problems later.

Safety Tips During Maintenance

Always turn off the main power before working on the box and wear proper safety equipment. Never touch internal wiring unless you are trained and qualified. Even simple checks can be dangerous if power is still on.

By following these guidelines and maintaining your power distribution box, you ensure a safe, reliable system that’s ready for whatever comes next.

Conclusion

A power distribution box directs electricity safely and efficiently throughout your system. It protects against overloads, simplifies power management, and works well in a variety of settings—from homes to factories and event venues. Though small, this box plays a crucial role in keeping your electrical setup safe and well-organized.

If you need help choosing the right power distribution box for your project, Zhengkai offers a wide selection of reliable, high-quality options designed to meet various needs and standards. Our team is ready to assist you in finding or designing the perfect solution for your system.

FAQs About Power Distribution Boxes

What is the difference between a panel and a PDB?

Generally, “panel” and “power distribution box (PDB)” refer to the same thing—they both distribute electricity to various circuits. The term “panel” is more common in homes, while “PDB” is often used in commercial or industrial environments.

Can I install one myself?

It’s not recommended unless you are a trained electrician. Installing a PDB involves working with live wiring, following safety codes, and careful planning. Mistakes can cause serious hazards like fires or electric shocks.

How often should it be inspected?

A visual inspection every few months is advisable. For homes, a professional check once a year is usually sufficient. Industrial and commercial setups may require more frequent inspections due to heavier usage.

What’s the lifespan of a PDB?

A quality power distribution box can last 20 to 30 years or longer. However, components like circuit breakers may need to be replaced sooner if they show signs of wear or damage.

Can it be upgraded later?

Yes! Many PDBs are designed to be expandable. You can add more circuits, breakers, or smart features as your power needs increase—just be sure the box has enough space and capacity.