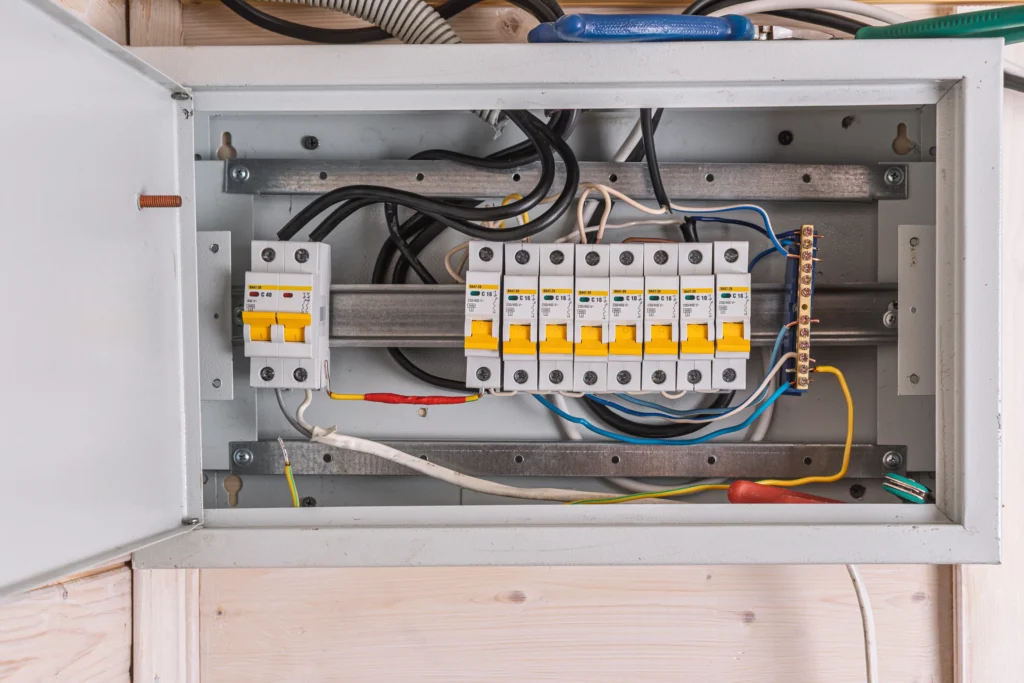

A distribution boxes acts as the load center and main distributor of electrical power within a building.

Also called a distribution board, panel board, breaker panel, or electric panel, it is the central hub in an electrical system that divides incoming power into various subsidiary circuits. Each circuit is safeguarded by a protective fuse or circuit breaker.

Inside a distribution box are components like circuit breakers, earth leakage units, doorbells, and timers. The building’s electrical power enters through the main feeding cable, which connects to the distribution board. From there, the power is distributed through the breakers to secondary circuits such as lighting and power outlets. Essentially, the distribution box ensures the safe and organized distribution of electricity throughout the property.

Get a Quote / DB Selection Help (Reply in 12 Hours)

Send the details below and we will recommend a matched DB configuration and provide a quotation:

- Application: indoor / outdoor / industrial / temporary power

- Number of ways (circuits): 4 / 6 / 8 / 12 / 18 / 24…

- Voltage & phase: 230V 1P / 400V 3P…

- IP rating: IP30–IP44 (indoor) / IP54–IP66 (outdoor)

- Enclosure material: ABS / PC / metal (optional)

- Protection devices: MCB only / +RCCB or RCBO / +SPD (optional)

What Is a Distribution Box (DB / Distribution Board)?

A distribution box (distribution board / DB box) receives incoming power from the mains supply and safely distributes it to multiple branch circuits. It improves safety by enabling protection against overload and short circuits, and it improves reliability by keeping circuits separated and clearly identified.

Distribution Box Components (Typical DB Components)

A distribution box structure can vary based on installation requirements, environment, and local electrical standards. Typical components include:

- Busbar: Conducts and distributes power to multiple outgoing circuits.

- Fuse links (or breakers): Interrupt excess current to protect wiring and equipment.

- Switches / isolator: Controls circuits and provides shut-off for maintenance.

- Bypass equipment (optional): Allows alternative routing or maintenance operations.

- Residual current protection (RSD/RCCB/RCBO): Detects leakage current and cuts off power to reduce electric shock risk.

- Surge protective device (SPD): Protects equipment from voltage spikes and surges.

- Earthing connection: Ensures proper grounding to maintain safety and system stability.

These components support residential and commercial installations by managing the incoming supply, distributing power across branch circuits, and protecting the system from overloads, faults, and leakage.

Key Safety and Design Considerations

- Protective devices must reliably interrupt overcurrent to protect wiring and connected devices.

- The enclosure must provide sufficient internal space to avoid overcrowded wiring.

- Materials should resist corrosion and aging for long-term durability.

- High-quality wiring and proper termination are essential for safety and reliability.

Need help confirming the right set of devices (MCB/RCCB/RCBO/SPD)? Send your requirements and get a reply within 12 hours.

Main Functions of a Distribution Box

The primary roles of a distribution box include:

- Dividing the main power supply into smaller sub-circuits based on their use.

- Protecting people and equipment by preventing short circuits and overloads.

- Sending power from the main source to different areas within a property.

Distribution boards can be customized to meet different wiring layouts, circuit quantities (ways), and environmental requirements such as IP protection.

Distribution Box Types / Distribution Board Types (Quick Comparison)

Use the table below to quickly identify which distribution box type best matches your application:

| Type | Typical Use | Key Feature | Notes |

|---|---|---|---|

| Main Breaker Panel | Primary distribution in a building | Includes a main breaker for shutoff and protection | Most common for residential/commercial |

| Main Lug Panel | Downstream distribution | No main breaker (uses upstream protection) | Often used as a sub-panel |

| Sub Panel | Local circuit distribution | Adds circuits near a specific area | No main disconnect switch |

| Transfer Switch Panel | Backup power integration | Switches between utility and generator | Manual or automatic |

| Panel Fuse Bank | Overcurrent protection & distribution | Uses fuse protection for circuits | Often used in solar setups |

| Unitized Panel | Industrial/commercial power centers | Includes metering and monitoring | For low-voltage distribution from MV lines |

| Industrial Lighting Panel | Industrial lighting control | Timed/controlled lighting circuits | Improves energy efficiency |

| Power Distribution Box (PDU/Distro) | Temporary/portable distribution | One input, multiple outputs | Often used for devices/equipment |

Types and Functions of Different Distribution Boxes

Main Lug Panel

This type of distribution box is typically used downstream of a main breaker. The line wires connect directly to the lugs. It can also serve as a sub-panel when linked to a breaker from the main panel. In an emergency or fire, a separate disconnect at the meter can act as the main breaker, cutting off power before it enters the building.

Sub Panel

Subpanels are ideal when multiple circuits are needed in one area. They are easy to install, safe, and efficient for homes. Connected to the main panel by a circuit, subpanels draw power and redistribute it locally to specific sections. Functioning as satellite breaker panels, they provide power distribution within a property. However, subpanels do not feature a main disconnection switch.

Transfer Switch

A transfer switch—a specialized subpanel—is used to switch power between two sources, such as regular electricity and a generator. It transfers generator power to the electrical system via the breaker panel. Transfer switches are useful for backup power during unstable weather or outages. There are two types:

- Manual Transfer Switch: Requires manual operation to shift load to backup power.

- Automatic Transfer Switch: Automatically shifts power to a generator during outages, preferred for convenience and seamless operation.

Panel Fuse Bank

This panel acts as the load center for a distribution system and protects circuits from overcurrent. It’s well-suited for solar power setups, where energy is stored on solar panels, then routed through the fuse bank before reaching the home’s electrical system.

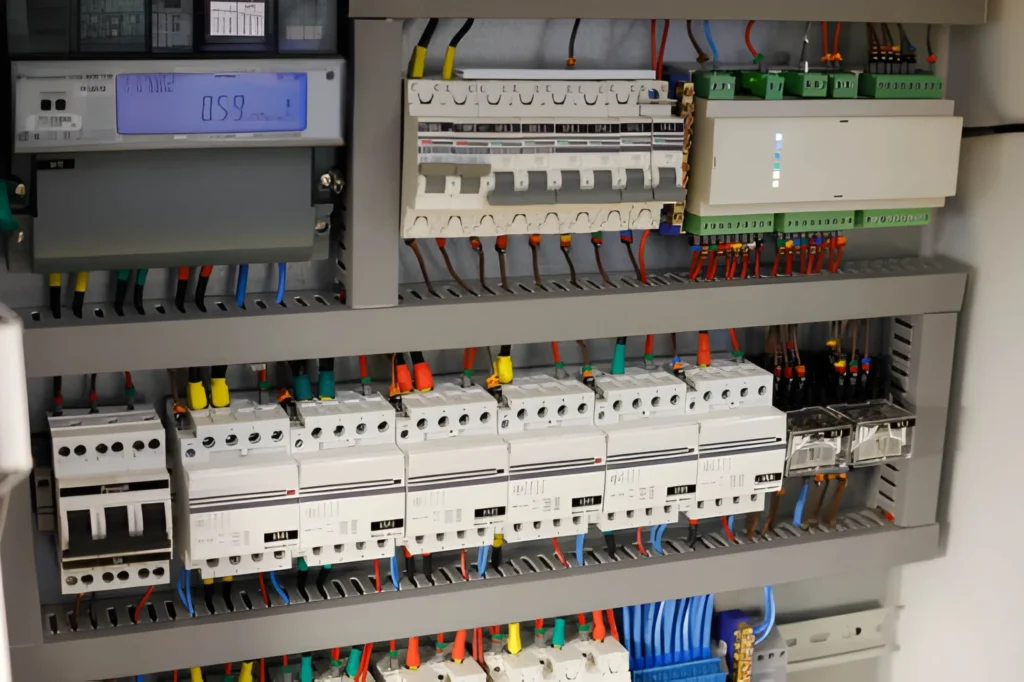

Unitized Panel

These panels contain electronic meters displaying electrical parameters. They are used in power centers to supply low voltage power from medium-voltage lines, commonly found in industrial and commercial settings.

Industrial Lighting Panel

Designed to reduce energy use in industrial facilities by programming lights to turn off during idle periods, helping to increase energy efficiency.

Power Distribution Box

Power distribution boxes, also known as Power Distribution Units (PDUs) or distros, play a vital role in safely distributing electricity from a power source to multiple devices within a circuit. With one input and several outputs, these boxes allow multiple devices to connect through the distro instead of directly to the power supply. This setup enhances safety while making power distribution more efficient and convenient.

These power distribution boxes come in various shapes, sizes, and designs, which can be customized based on specific needs. They can vary in input and output voltages, the number of input connections, and often include added safety features such as Miniature Circuit Breakers (MCBs) and Residual Current Breakers (RCBs).

One major benefit of power distribution boxes is that they reduce the need for numerous direct connections to the power source. This limits excess wiring, saving energy and reducing clutter in the circuit. Streamlined wiring not only improves operational efficiency but also minimizes power wastage. Furthermore, fewer exposed wires create a safer environment for both workers and visitors by reducing the risk of trips and entanglements caused by cables.

Checkout Our Range of Distribution Boxes!

FAQ

What is an electrical distribution box?

A distribution box (distribution board/DB box) distributes incoming power to multiple circuits and typically houses protective devices such as breakers and optional leakage/surge protection.

Distribution box vs distribution board—what’s the difference?

They are often used interchangeably. “DB/distribution board” is common in IEC markets, while “panel” terminology is common in North America.

What are the main distribution box components?

Common components include busbar, breakers (MCB), neutral/earth bars, enclosure, and optional RCCB/RCBO and SPD.

What is a DB box in electrical wiring?

A DB box usually refers to a distribution board enclosure, commonly specified by number of ways, installation method, and IP rating.

How do I choose the number of ways?

Count the required circuits and allow for future expansion. Typical options include 4/6/8/12/18/24 ways.

When do I need RCCB/RCBO and SPD?

RCCB/RCBO provides leakage protection for safety. SPD is recommended where surge risk exists (lightning, unstable grid, sensitive equipment).

Request a Quote: Distribution Box / DB Box

Send your requirements (application, ways, IP rating, voltage/phase, and required protection devices). We will respond within 12 hours with a matched recommendation and quotation.