Have you ever had plenty of power available—yet still struggled to get it safely to the right tools, panels, or work zones? That’s exactly where electrical distro boxes earn their keep. Whether you’re running a temporary setup, expanding an industrial line, or powering a site with multiple crews, you need distribution that’s safe, organized, and easy to scale.

In this guide, we’ll break down how electrical distro boxes work, which specs actually matter, and how to choose the right configuration for your application. Along the way, we’ll cover common industrial use cases, smart monitoring options, and the practical tradeoffs that separate a “good enough” box from one you’ll trust at 2 a.m. when uptime matters.

What electrical distro boxes do (and why you might need one)

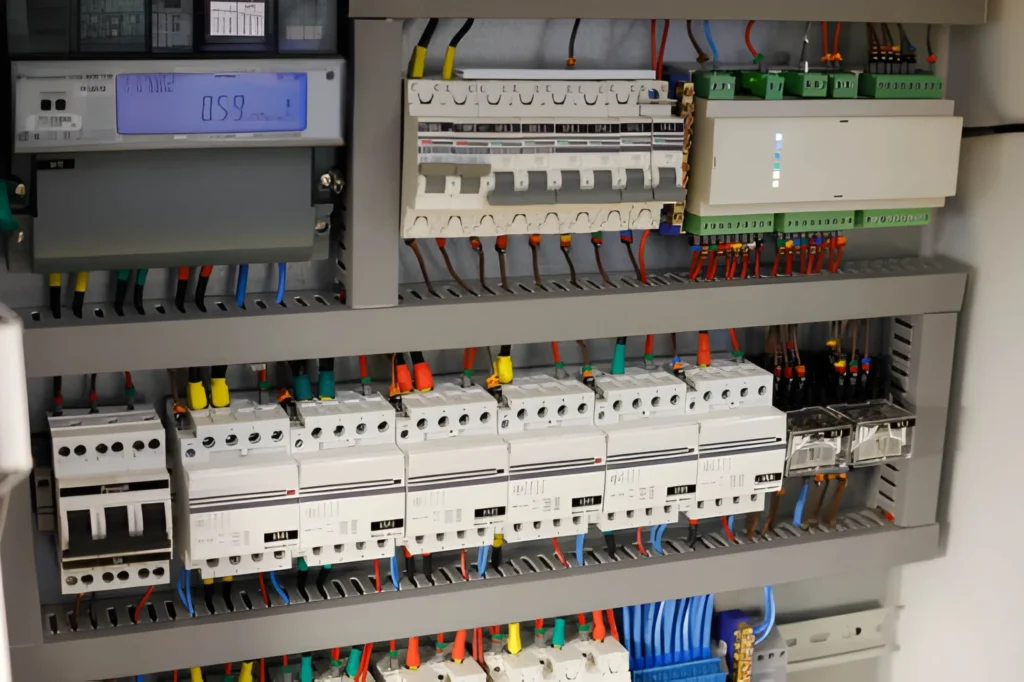

At a basic level, electrical distro boxes take one power input and split it into multiple protected outputs. Think of them as the traffic controller for your electricity: they route power where it needs to go and help prevent overloads, faults, and chaos.

You’ll typically use them when you need:

- Multiple circuits from one source (generator, mains, or upstream panel)

- Safer temporary power distribution for people and equipment

- Faster setup/teardown with standardized connectors

- A cleaner way to manage loads across phases

Common environments include construction sites, industrial maintenance shutdowns, warehouses, outdoor events, data closets, and manufacturing expansions.

| Scenario | What you’re trying to solve | Why a distro box helps |

|---|---|---|

| Temporary jobsite power | Many tools, rotating crews | Breakers + labeled outputs keep things safe and tidy |

| Plant maintenance outage | Multiple trades in different zones | Centralized distribution reduces “creative” wiring |

| Outdoor setup | Weather + long cable runs | Rugged enclosures and protected receptacles reduce risk |

Specs that actually matter when evaluating a distro box

Not all power distribution is created equal. When you compare electrical distro boxes, focus on specs that affect safety, compatibility, and future expansion—not just how many outlets you get.

1) Voltage and phase

Start with the basics: single-phase vs three-phase and your operating voltage (common examples include 120/240V single-phase or 120/208V / 277/480V three-phase). A mismatch here is a non-starter.

2) Total amperage and upstream protection

Look at the main breaker rating and the maximum input current. For industrial setups, you’ll often see higher-capacity configurations with feeder inputs (for example, cam-style connectors) and multiple branch circuits.

3) Branch circuit layout (and breaker quality)

A good unit offers:

- Clear breaker labeling

- Proper spacing and access

- Reliable breaker brands and consistent trip curves

- Logical grouping for phase balancing

4) Connector types and receptacles

This is where “it should fit” turns into “why doesn’t it fit?” quickly. Pay attention to:

- Inlet style (hardwire, pin-and-sleeve, cam-style, twist-lock)

- Outlet standards (IEC/CEE, NEMA styles, single-phase and three-phase receptacles)

- Cable strain relief and locking mechanisms

5) Environmental rating (indoor vs outdoor)

If water, dust, or washdown is in play, enclosure protection matters. Look for enclosure ratings appropriate to your environment (for example, weather-resistant enclosures for outdoor temporary power distribution).

6) Metering and monitoring

Many electrical distro boxes now include built-in metering—helpful for load management, cost allocation, and troubleshooting.

| Spec | What it impacts | What “good” looks like |

|---|---|---|

| Voltage + phase | Compatibility | Matches your site power and loads |

| Main amp rating | Capacity | Supports peak demand with headroom |

| Branch circuit count | Flexibility | Enough circuits for today + growth |

| Enclosure rating | Reliability | Suitable for dust/water exposure |

| Metering | Visibility | Clear readings, alarms, optional logging |

Types of electrical distro boxes and where each fits best

The “right” design depends on mobility, power level, and how many endpoints you need. Here are the common categories you’ll see in commercial and industrial buying decisions.

Portable distribution boxes

These are designed for quick deployment. You’ll often see them used for temporary jobsite power, maintenance teams, and mobile operations.

Wall-mount or fixed industrial distribution boxes

A more permanent approach for facilities that need dedicated distribution at specific zones or work cells.

Rack-mount distribution (IT, AV, control rooms)

Useful where space, cable management, and standardized mounting matter.

Spider boxes / jobsite power boxes

Built for rugged conditions and fast access—great for construction and industrial shutdown environments with many hand tools and lighting loads.

High-amperage feeder distro (cam-style and similar)

Designed to take a large feeder input and split into multiple outputs, often including three-phase receptacles and protected branch circuits.

| Type | Best for | Strengths | Watch-outs |

|---|---|---|---|

| Portable | Moving crews, temporary setups | Fast setup, flexible | Can be under-specced for heavy loads |

| Wall-mount | Fixed zones, repeat use | Clean installation | Less flexible if needs change |

| Spider/jobsite | Tough environments | Rugged + accessible | Verify GFCI/RCD needs and receptacle mix |

| Feeder distro | Large temporary distribution | Scales well | Requires careful load planning |

Safety and compliance: what to look for (and what to avoid)

If you’re buying or specifying electrical distro boxes for real operations, safety isn’t a bonus feature—it’s the point. The best units help prevent shock hazards, overloads, and miswiring mistakes that lead to downtime (or worse).

Key features and practices to prioritize:

- Ground-fault protection where required (GFCI/RCD protection depends on use case and regional codes)

- Proper neutral and ground bonding design (and clarity on when bonding is allowed)

- Phase balancing support (especially for three-phase loads)

- Clear labeling for circuits, voltage, and maximum loads

- Robust cable strain relief and protected receptacles

- Consideration for arc-flash risk in higher-energy environments (procedures matter as much as the box)

And a practical tip: if your team regularly “borrows” outlets from wherever they can find them, a well-planned distro setup reduces improvisation. Electricity loves improvisation about as much as water loves open laptops.

| Safety element | Why it matters | What to verify |

|---|---|---|

| Ground-fault protection | Shock risk reduction | Correct rating and test method |

| Breaker coordination | Prevents nuisance trips | Logical branch sizing |

| Enclosure protection | Dust/water damage control | Appropriate environmental rating |

| Labeling | Faster troubleshooting | Durable, readable identifiers |

Smart features: monitoring, alarms, and “why is this circuit hot?”

Modern electrical distro boxes increasingly include smart capabilities—not because it’s trendy, but because visibility saves time. If you’ve ever chased a mysterious trip across multiple circuits, you know how valuable clean power data can be.

Common smart/advanced options include:

- Digital power meters showing volts/amps/kW/kWh

- Branch circuit monitoring (seeing load by circuit, not just total)

- Alarm thresholds for overloads or phase imbalance

- Data logging for audits, billing, or energy management programs

- Remote communications (often via industrial protocols)

These features are especially helpful in industrial facilities, rental fleets, and multi-tenant temporary setups where you need to understand usage patterns.

| Smart feature | What you gain | Best use case |

|---|---|---|

| Built-in metering | Real-time visibility | Load management, troubleshooting |

| Branch monitoring | Circuit-level insight | Complex multi-team setups |

| Logging | Historical proof | Billing, audits, performance tracking |

| Alarms | Faster response | Preventing overload downtime |

How to choose the right electrical distro box for your application

When you’re in commercial investigation mode, you’re not just asking “what’s available?” You’re asking “what will work reliably in our environment?” Use these decision filters to narrow options quickly.

Step 1: Define your loads (today and 6–18 months out)

List your typical equipment and estimate demand. Include surge currents for motors, heaters, welders, or compressors.

Step 2: Confirm source power and connectors

Match your input power (voltage, phase, available upstream protection) and make sure the inlet style fits your site reality.

Step 3: Choose your output mix

Do you need mostly 120V convenience outlets? A blend of single- and three-phase receptacles? Longer cable runs? This drives branch layout and enclosure format.

Step 4: Decide how much visibility you need

If downtime is expensive—or you bill power to projects—consider metered electrical distro boxes. Even basic metering can pay for itself in troubleshooting time.

Step 5: Check durability for the environment

Indoor clean space? Outdoor mud and rain? Industrial dust and vibration? The enclosure, covers, and hardware must match conditions.

If you want a second set of eyes on sizing, receptacle mix, or metering options, you can always send us an inquiry or request a quote based on your load list—we’ll help you sanity-check the configuration without turning it into a hard sell.

| Your priority | What to optimize | What to look for |

|---|---|---|

| Fast deployment | Portability | Handles, compact layout, quick-connect input |

| Industrial reliability | Ruggedness | Heavy-duty enclosure, secure receptacles |

| Flexible outputs | Circuit variety | Mixed receptacles, clear labeling |

| Power visibility | Monitoring | Digital meter, alarms, branch monitoring |

Cost, rental vs purchase, and maintenance reality

The purchase price is only part of the story. With electrical distro boxes, the bigger cost drivers often show up later as downtime, repairs, and operational friction.

When renting makes sense

- Short-term projects or seasonal peaks

- Uncertain requirements (you’re still learning what you need)

- You want someone else handling maintenance and inspection cycles

When buying makes sense

- Repeated use across projects or sites

- Standardization matters (training, spare parts, common cables)

- You want consistent metering and documentation

Maintenance considerations:

- Routine inspection of receptacles, breakers, labels, and strain relief

- Testing ground-fault devices on schedule

- Keeping connectors clean and protected during storage/transport

| Decision factor | Rent | Buy |

|---|---|---|

| Short-term use | ✅ | ❌ |

| Frequent repeat use | ❌ | ✅ |

| Standardization across teams | Maybe | ✅ |

| Upfront budget constraints | ✅ | ❌ |

Conclusion

Choosing electrical distro boxes well is about more than “how many outlets.” It’s about matching your source power, load profile, environment, and safety requirements so distribution stays predictable under pressure. When you evaluate the right specs—voltage and phase, amperage capacity, breaker layout, enclosure durability, and metering—you end up with a system that’s easier to deploy, easier to troubleshoot, and less likely to surprise you at the worst possible moment.

If you take one thing away, let it be this: plan your distribution the way you plan your workload. Map the loads, leave headroom, prioritize protection, and consider visibility tools like metering when uptime matters. With the right electrical distro boxes, you’ll spend less time managing power—and more time actually getting work done.

FAQ

What does an electric power meter measure?

An electric power meter typically measures electrical parameters such as voltage, current, power (kW), and energy consumption (kWh). Some meters also track power factor, frequency, and demand peaks.

What’s the difference between kW and kWh on a power meter?

kW shows real-time power draw (how fast you’re using electricity). kWh shows total energy used over time (how much electricity you used), which is what most billing is based on.

How accurate are digital electric power meters?

Accuracy depends on the meter class and installation quality. Many digital meters are very accurate when properly installed within their specified current range and with correct wiring and calibration.

Can a power meter help find overloaded circuits?

Yes. A power meter can reveal high current draw, demand spikes, or phase imbalance. When used with branch monitoring, it becomes much easier to identify which circuits are approaching their limits.

Do electric power meters work on three-phase systems?

Many models are designed specifically for three-phase power. You need to match the meter to the wiring configuration (such as wye or delta), voltage range, and current sensor type.