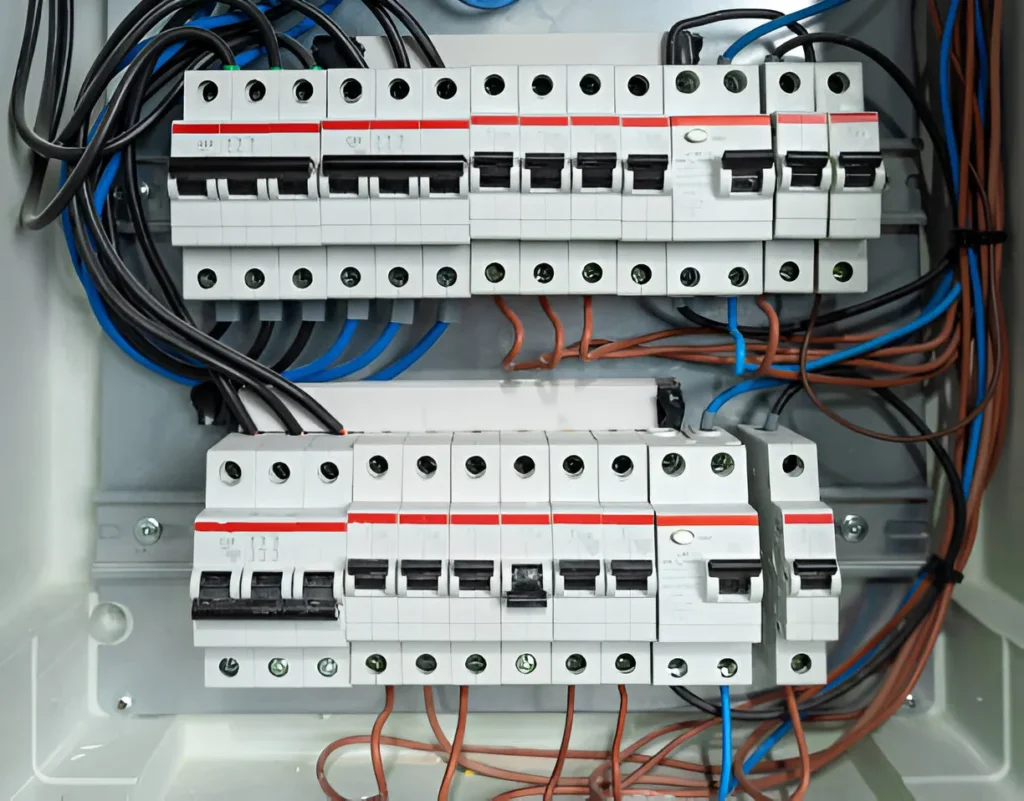

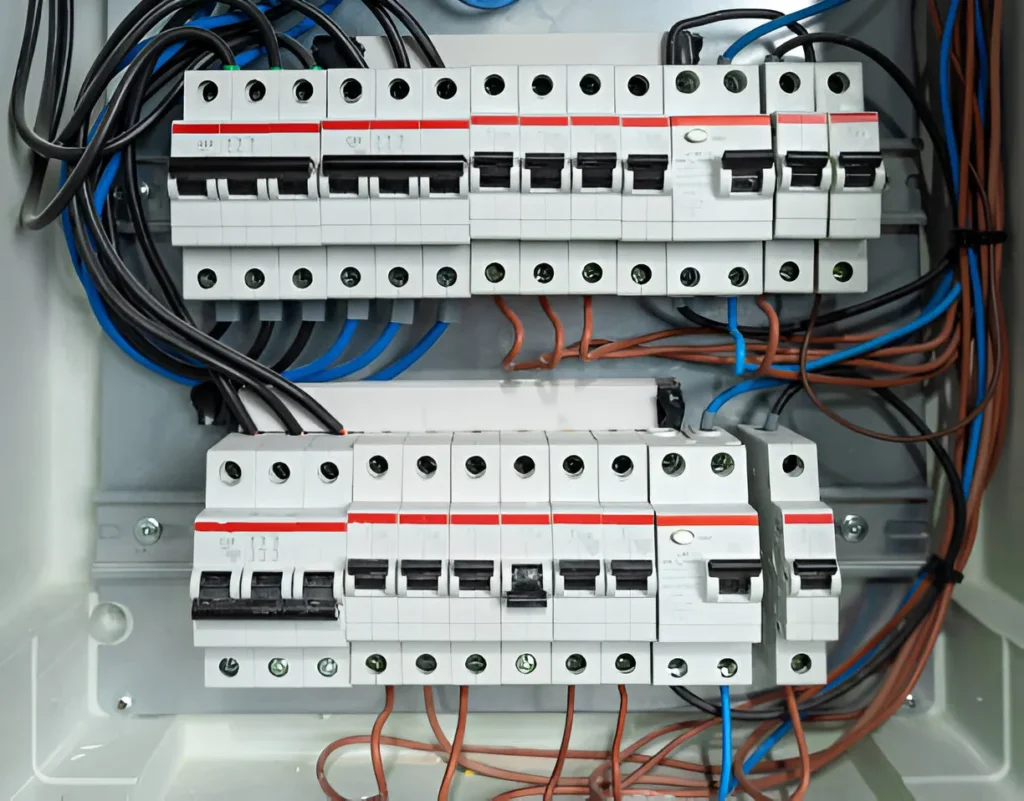

What is a Motor Protection Circuit Breaker (MPCB)?

A Motor Protection Circuit Breaker (MPCB) is a specialized electrical device designed to safeguard electric motors from damage caused by various electrical faults.It combines the capabilities of a molded case circuit breaker with dedicated motor protection features, making it an essential component in industrial and commercial applications.

Working Principle of MPCBs

Think of an MPCB as your motor’s personal bodyguard, constantly on alert through a sophisticated combination of thermal and electromagnetic mechanisms. Like a vigilant security system, it monitors current flow and springs into action when it detects potential threats. When dangerous situations arise – whether it’s an overcurrent surge or a short circuit – the MPCB steps in immediately, disconnecting the circuit faster than you can blink to save your motor from costly damage.

Thermal Protection

The thermal protection system works like a fever monitor for your motor. Using bimetallic strips that bend when heated, it keeps a watchful eye on heat buildup. What makes this system particularly clever is its time-delay feature – it’s smart enough to distinguish between the normal high current during motor startup (which can be 6-8 times the rated current) and genuine overload conditions. This prevents unnecessary trips during normal operations while ensuring your motor doesn’t cook itself during sustained overloads.

Magnetic Protection

While thermal protection handles the slow-burning threats, magnetic protection is your high-speed security force. Using electromagnetic solenoids, it responds to short circuits and severe overcurrent situations in milliseconds – typically within 10-20ms. This lightning-fast response is crucial because short-circuit currents can reach up to 20 times the normal operating current, potentially destroying your motor in the blink of an eye.

Functions of MPCBs in Industrial Applications

Overload Protection

Think of overload protection as your motor’s built-in fitness tracker. When your motor starts struggling – whether it’s gasping for breath under a jammed rotor (drawing 6-7 times normal current), huffing through frequent start-stops (causing temperature spikes up to 150°C), or limping along with a missing phase – the MPCB steps in. Using precise thermal sensing, it monitors current levels and cuts power before your motor burns out, typically responding within 60-120 seconds of detecting sustained overload conditions.

Short Circuit Protection

Short circuits are like electrical heart attacks – sudden, severe, and potentially fatal for your motor. When a low-resistance path creates current surges up to 20 times the normal rating, your MPCB becomes an emergency responder. It detects and interrupts these dangerous currents in milliseconds (typically under 10ms), preventing catastrophic damage that could cost thousands in repairs and downtime.

Phase Protection: The Three-Phase Balance Keeper

For three-phase motors, phase balance is like maintaining a perfect triangle of power. Advanced MPCBs act as expert jugglers, constantly monitoring the balance between phases. They detect both complete phase loss and subtle imbalances (typically triggering at 30% voltage difference between phases), protecting your motor from the damaging effects of uneven power distribution. This feature alone can extend motor life by up to 50% under challenging power conditions.

Advantages of Using MPCBs in Industrial Settings

MPCBs offer several key benefits over traditional protection devices:

- Compact size while delivering high performance

- Adjustable current settings for application-specific protection

- No requirement for external thermal overload relays

- Extended operating life compared to alternative protection devices

- Low maintenance requirements and reduced downtime

Applications of MPCBs in Industry

MPCBs find extensive use across various industrial and commercial settings:

Manufacturing Sector

These devices protect motors in manufacturing plants, conveyor systems, and industrial machinery.

HVAC Applications

MPCBs safeguard motors in cooling towers, rooftop air conditioners, and air handling units.

Commercial Buildings

They protect elevator motors, water pumps, and other building service equipment.

Specialized Equipment

MPCBs are crucial for protecting motors in:

- Industrial conveyor belts

- Injection and extraction fans

- Compressors and pumping system

FAQs

1.What are the applications of motor protection circuit breaker?

MPCBs protect motors in manufacturing equipment, HVAC systems, and industrial machinery. Common applications include conveyor systems, pumps, compressors, fans, and elevator motors.

2.What is the difference between an MCCB and an MPCB?

MPCBs are specialized for motor protection with built-in overload and phase protection features, while MCCBs are general-purpose circuit breakers that need additional components for motor protection. MPCBs can handle motor starting currents without tripping, unlike MCCBs.

3.Can an MPCB be used in residential applications?

Yes, MPCBs can protect motors in residential appliances like air conditioners and washing machines, but they are typically more expensive than standard residential circuit breakers and usually unnecessary for basic home applications.