Characteristics and Challenges of Hazardous Environments

What makes hazardous environments so perilous for electric motors? It’s not just one factor—it’s a cocktail of extreme conditions. These environments often feature explosive gases, combustible dust, or corrosive chemicals, making them ticking time bombs for unprotected machinery. Without proper motor protection, the risks to equipment and operations become even more severe. Industries like oil and gas, mining, and chemical manufacturing operate in such settings daily, where the stakes are high.

One major challenge is balancing safety with operational efficiency. Motors in these environments face risks like overheating, short circuits, or even igniting flammable substances. Picture this: a motor sparking in a coal mine filled with fine dust particles. The result? A catastrophic explosion that could halt operations and endanger lives. Implementing effective motor protection strategies is essential to addressing these risks and designing solutions that safeguard both people and machinery.

Types of Explosion-Proof Motors and Their Applications

Not all motors are built to withstand hazardous conditions. That’s where explosion-proof motors come in—designed to prevent internal sparks or heat from igniting external hazards. But did you know there are different types of explosion-proof motors tailored for specific risks? Let’s break it down:

- Class I Motors: These are your go-to for areas with flammable gases or vapors, such as oil refineries. They’re engineered to operate safely around volatile substances like methane or propane

- Class II Motors: Perfect for environments dealing with combustible dust, such as grain mills or sugar factories. Dust might seem harmless, but when suspended in air, it can be highly explosive.

- Class III Motors: Designed for industries like textiles or woodworking, where fibers and flyings pose a fire hazard.

Each type adheres to strict certifications like ATEX (Europe) or NEC (United States), ensuring they meet safety standards. Selecting the right motor isn’t just about compliance; it’s about ensuring your operations run smoothly without compromising safety or efficiency.

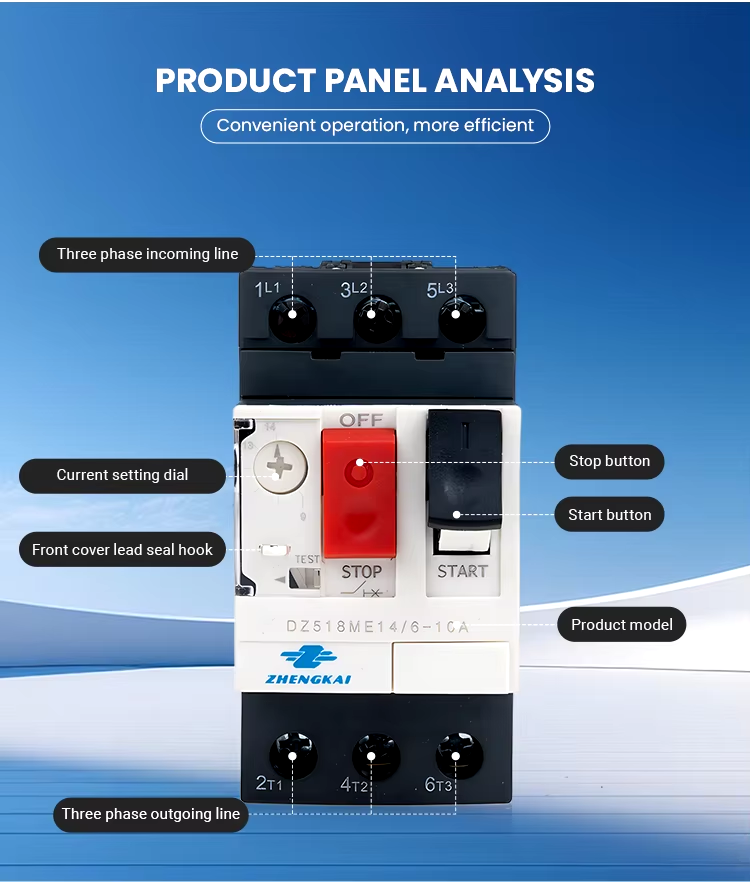

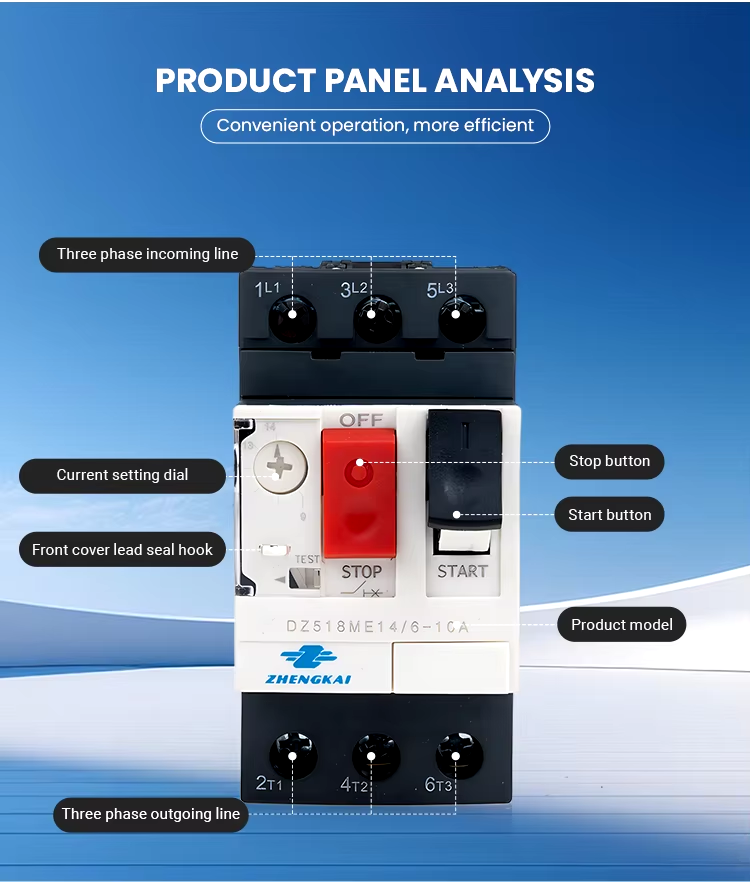

The Role of Motor Protection Circuit Breakers

If you’re already using explosion-proof motors, do you really need additional protection? Absolutely! This is where motor protection circuit breakers (MPCBs) step in as the unsung heroes of motor safety. Think of them as the vigilant guards standing between your motor and electrical disasters.

MPCBs protect against common electrical faults like overloads, short circuits, and phase failures. For instance, imagine a conveyor belt motor in a mining operation suddenly drawing excessive current due to a jammed rotor. Instead of overheating and risking ignition, the MPCB trips instantly to cut off power—preventing damage and potential accidents.

Modern MPCBs offer advanced features like thermal-magnetic protection and adjustable settings tailored to different motor sizes. Beyond safety, these devices extend motor lifespan by reducing wear and tear caused by electrical issues. They’re not just an added layer of protection; they’re an investment in operational reliability.

Installation and Maintenance

Even the most advanced motors and circuit breakers won’t perform well without proper installation and maintenance. Here’s how to get it right:

- Proper Installation: Follow manufacturer guidelines meticulously. Ensure all seals are intact to prevent gases or dust from entering the motor housing. A single loose seal can compromise the explosion-proof design.

- Routine Inspections: Regularly check for signs of wear and tear like corrosion, loose connections, or unusual vibrations. Early detection is key to preventing costly breakdowns.

- Testing Equipment: Use specialized tools to test insulation resistance and other critical parameters. This ensures your equipment remains compliant with safety standards.

- Employee Training: Equip your team with the knowledge they need to handle hazardous equipment safely. A well-trained workforce can identify potential issues before they escalate into major problems.

By investing time in proper installation and maintenance practices, you’re not just protecting your equipment—you’re safeguarding your entire operation from downtime and danger.