Moulded Case Circuit Breaker

Zhengkai Electric’s Moulded Case Circuit Breakers (MCCBs) provide reliable protection against overloads, short circuits, and electrical faults.

With durable molded insulation and adjustable trip settings, Zhengkai MCCBs ensure safe, efficient power distribution across commercial, industrial, and residential applications.

Product Overview

A Moulded Case Circuit Breaker provides effective protection by automatically disconnecting power during fault conditions such as overloads or short circuits.

MCCBs come equipped with adjustable trip settings, allowing customization to different load requirements and making them highly versatile.

Their rated currents typically range from 16A up to 6000A or more, accommodating low to very high power circuits. Designed to meet international standards such as IEC 60947-2 and UL 489, MCCBs offer compliance and performance trusted globally.

Key Features and Technical Specifications

Thermal-Magnetic Trip Mechanism: Combines thermal protection for gradual overloads and magnetic protection for instant short circuits, providing comprehensive circuit safeguarding.

Adjustable Trip Settings: Enables precise tuning of trip thresholds to match specific application demands, increasing system flexibility and protection accuracy.

High Breaking Capacity: MCCBs can interrupt high fault currents, with breaking capacities reaching up to 200kA, ensuring system safety even under severe electrical stresses.

Durable Molded Insulating Case: Protects internal components from dust, moisture, mechanical impact, and environmental factors, enhancing durability and reliability.

Voltage and Pole Variants: Available in multiple configurations — single-pole to four-pole, with voltage ratings up to 1000V AC and DC systems.

Compliance and Certification: Meets international safety and performance standards, including UL 489, IEC 60947-2, and CSA certifications, delivering global acceptance and trust.

Types and Applications

MCCBs are available in various types tailored for different electrical loads and environments:

B, C, D, and Z Trip Curves: Each suited for specific load types, including residential lighting, industrial motors, transformers, and highly sensitive electronic equipment.

Single-phase and Three-phase Systems: Compatible with multiple power supply configurations across residential, commercial, and industrial settings.

Industrial and Commercial Protection: Ideal for factories, warehouses, medical equipment, elevators, HVAC systems, and power control centers.

Versatile Installation: Suitable for use as main switches, branch circuit protection, or motor overload safeguarding.

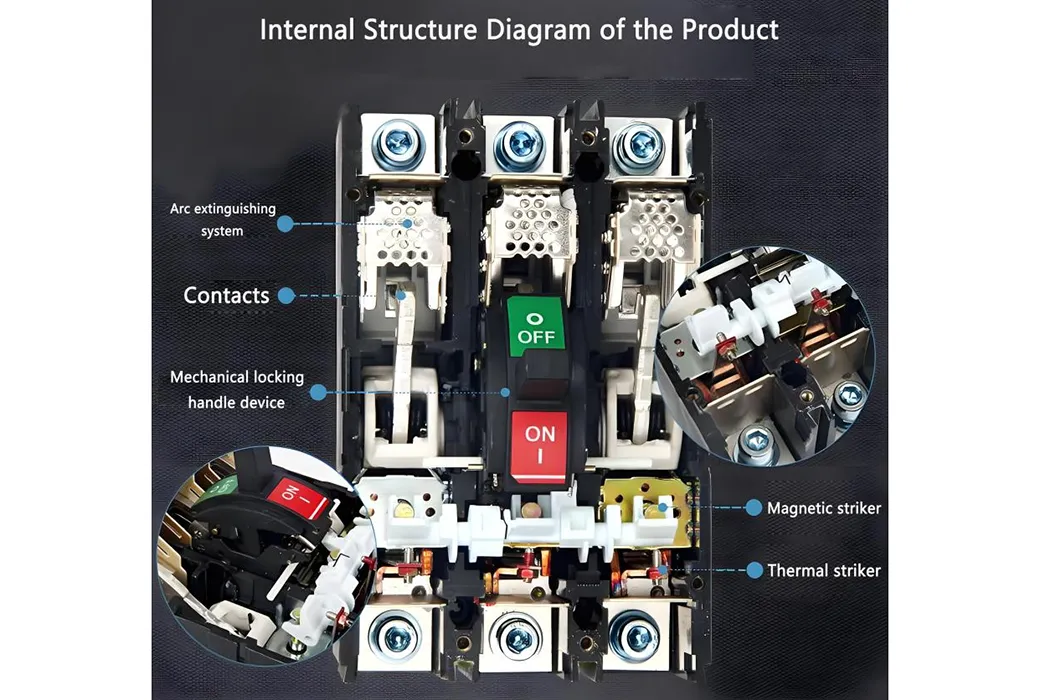

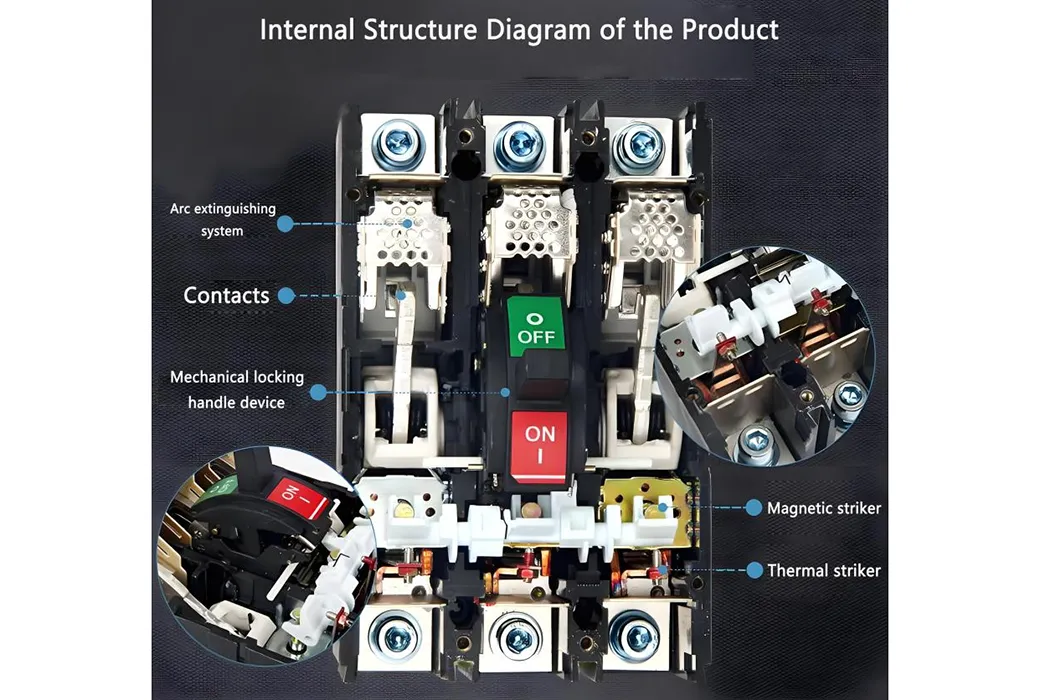

Internal Structure

MCCBs integrate a thermal bimetallic strip and electromagnetic solenoid within the molded case. The thermal element reacts to prolonged overload by bending to trip the breaker, while the electromagnetic coil instantly trips during short circuits.

Additionally, built-in arc extinguishing chambers safely dissipate electric arcs generated during fault interruption, enhancing operator safety and equipment protection.

Maintenance and Reliability

Routine inspection ensures consistent MCCB performance. Maintenance steps include:

Visual inspection for insulation integrity and contact wear.

Mechanical lubrication of moving parts.

Cleaning to remove accumulated dust or debris.

Functional testing of trip mechanisms to verify accurate operation. These practices extend MCCB lifespan and prevent unexpected failures in critical applications.

Moulded Case Circuit Breaker (MCCB) vs Traditional Circuit Breaker

| Feature | Moulded Case Circuit Breaker (MCCB) | Traditional Circuit Breaker (MCB) |

|---|---|---|

| Current Rating | Wide range from 15A up to 2,500A or higher | Generally 0.5A to 125A |

| Interrupting Capacity | High interrupting capacity, typically 10kA to 100kA | Lower interrupting capacity, up to about 15kA |

| Trip Settings | Adjustable thermal-magnetic or electronic trip settings | Fixed, non-adjustable trip characteristics |

| Construction | Durable molded insulating case for protection and heat dissipation | Simpler construction with less robust casing |

| Voltage Rating | Up to 1,000V AC or DC | Typically between 120V and 690V |

| Pole Configuration | Multiple configurations (1 to 4 poles), common in 3- and 4-pole types | Usually 1 to 4 poles, often for single-phase or small loads |

| Typical Applications | Industrial and commercial electrical systems including motor protection, main distribution | Residential/commercial branch circuits, light loads |

| Size and Installation | Larger size, requires dedicated enclosures or switchgear | Compact, panel-mounted DIN rail installation |

| Maintenance | Serviceable components, modular design for upkeep | Usually sealed units, replaced when faulty |

| Cost | Higher cost due to advanced features and higher capacity | Lower cost, suitable for less demanding applications |

| Safety Features | Enhanced safety with trip indicators, current limiting, and arc extinguishing | Basic trip function, limited advanced safety features |

| Environmental Resistance | High resistance to dust, moisture, and mechanical impact | Lower environmental protection |

| Typical Use Environment | Harsh industrial, commercial, and heavy-duty settings | Residential, light commercial, and less demanding settings |