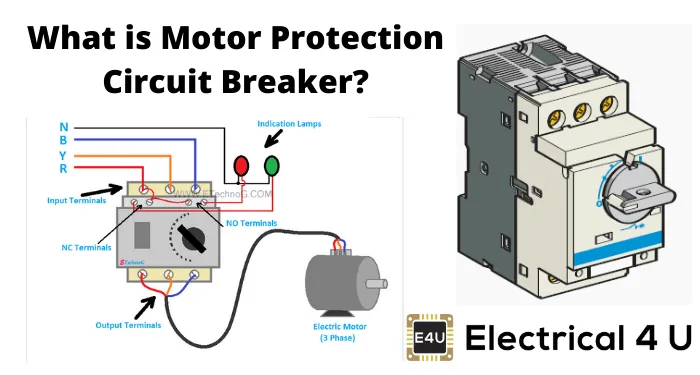

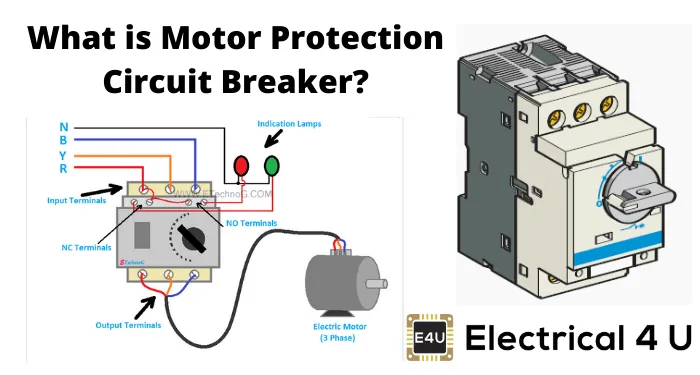

A motor protection circuit breaker is a device designed to protect electric motors from overloads and short circuits, ensuring safe operation and preventing equipment damage.

This blog will explore the functions, types, and applications of motor protection circuit breakers to provide a comprehensive understanding of their importance in various industries.

What is Motor Protection Circuit Breaker?

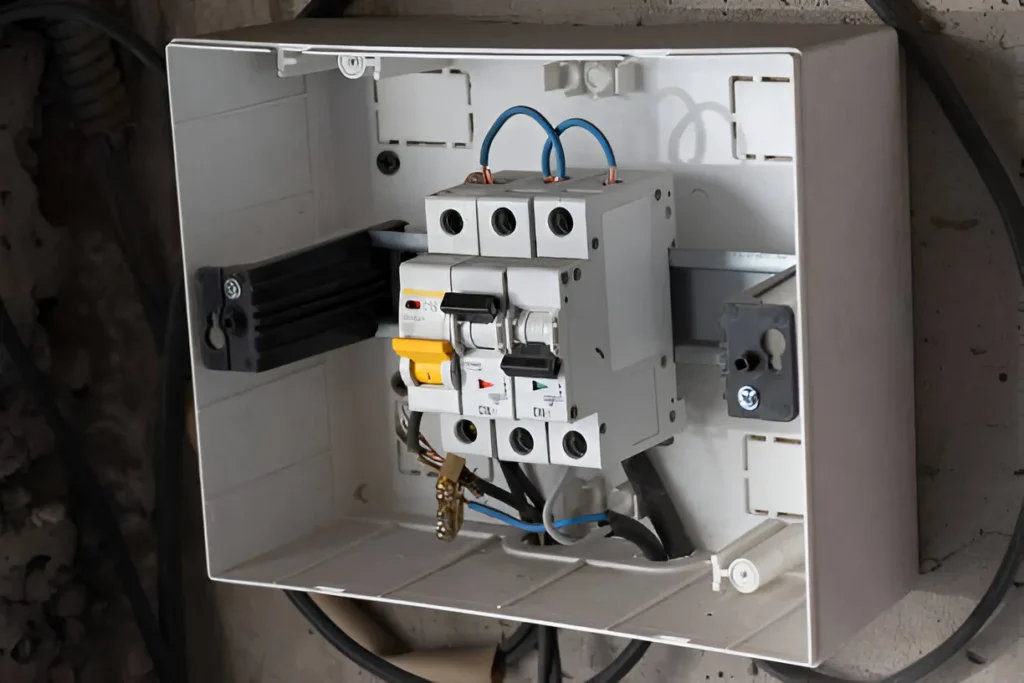

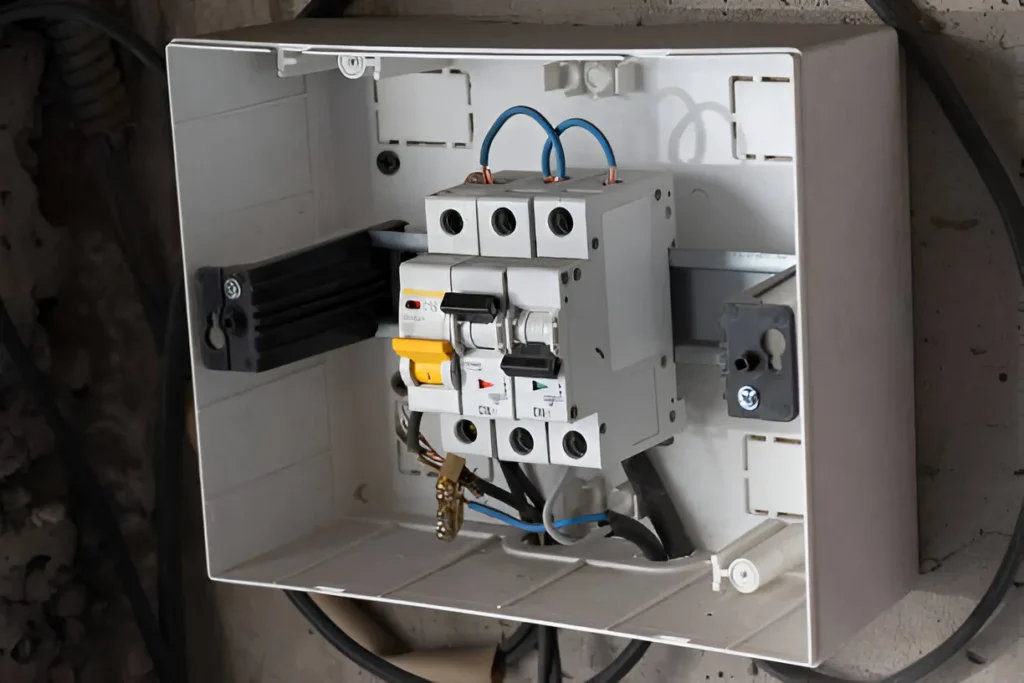

A motor protection circuit breaker (MPCB) is a crucial device designed to protect electric motors from overloads and short circuits. It ensures the safe operation of motors by automatically disconnecting the power supply when it detects abnormal conditions.

MPCBs combine the functions of a traditional circuit breaker with additional features tailored for motor protection. They monitor the motor’s current and temperature, providing safeguards against overheating and excessive current draw. This prevents potential damage to the motor windings and associated equipment.

MPCBs can be adjusted to match specific motor ratings, allowing for customized protection settings. They often include features such as phase failure detection, which identifies imbalances in the electrical supply that could harm the motor.

In industrial applications, MPCBs play a vital role in maintaining operational efficiency and reducing downtime caused by motor failures. Their reliability makes them essential components in various electrical systems.

What is the function of a motor circuit breaker?

A motor circuit breaker (MCB) serves multiple critical functions in electrical systems. Primarily, it protects electric motors from overloads and short circuits. By monitoring the current flowing through the motor, the MCB can detect excessive current that may indicate an overload condition.

When an overload occurs, the MCB automatically interrupts the power supply, preventing damage to the motor and its components. This automatic disconnection helps maintain system integrity and prolongs equipment life.

Additionally, MCBs provide protection against phase failure. They can detect imbalances in the electrical supply, which can lead to overheating or failure of the motor. Some models also feature adjustable settings, allowing customization based on specific motor ratings and operational requirements.

Types of Motor Protection Circuit Breakers

Motor Protection Circuit Breakers (MPCBs) are divided into three main types, each with unique protective characteristics and application scenarios.

Thermal MPCBs

utilize bimetallic strips or electronic thermal overload relays to detect and protect motors from overload conditions. This type of circuit breaker monitors motor temperature and triggers when current exceeds preset limits for a specific duration.

Magnetic MPCBs

Magnetic MPCBs, also called magnetic contactors or magnetic motor starters, offer short circuit and motor overload protection. They rely on electromagnetic principles to detect short circuits and provide rapid disconnection of the motor circuit.

Electronic MPCBs

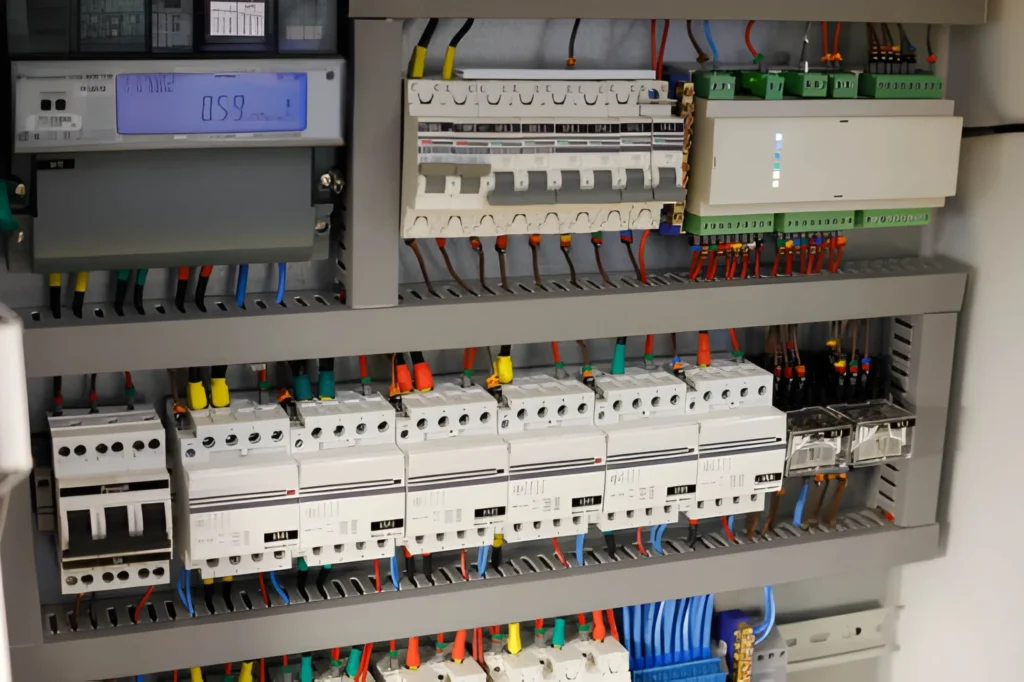

Electronic MPCBs employ microprocessor-based technology to monitor motor parameters such as current and temperature. These breakers offer precise motor protection, diagnostic capabilities, and advanced features including motor phase loss protection, phase imbalance detection, and communication interfaces.

Applications of Motor Protection Circuit Breakers

Industrial Automation

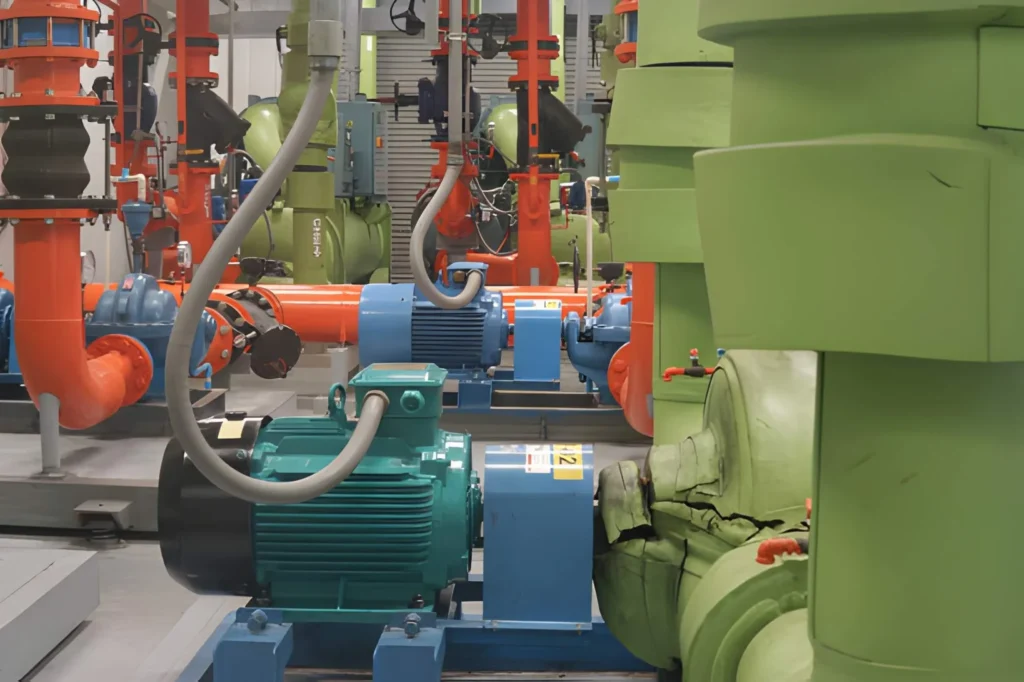

Motor protection circuit breakers (MPCBs) are widely used in industrial automation systems. They protect motors driving conveyors, pumps, and compressors from overloads and short circuits. By ensuring the reliable operation of these motors, MPCBs help maintain production efficiency and reduce downtime.

HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, MPCBs safeguard fan motors and compressor motors. They prevent overheating and potential damage due to electrical faults. This protection is essential for maintaining optimal performance and energy efficiency in HVAC applications.

Agricultural Equipment

MPCBs are essential in agricultural machinery, such as irrigation pumps and grain handling systems. They protect electric motors from damage caused by overloads during high-demand operations. This protection enhances the reliability of agricultural equipment, ensuring consistent performance.

Construction Machinery

Construction equipment, including cranes and excavators, relies on MPCBs for motor protection. These circuit breakers shield motors from electrical faults that could lead to costly repairs or operational delays. Their use ensures safety and reliability in demanding construction environments.

Renewable Energy Systems

In renewable energy applications, such as wind turbines and solar tracking systems, MPCBs protect the motors that control movement and energy generation. They help prevent failures due to electrical issues, contributing to the overall efficiency and longevity of renewable energy systems.

What is the difference between a circuit breaker and a motor circuit protector?

Here are the key differences between circuit breakers and motor circuit protectors:

Design Features

- Circuit breakers: Basic thermal and magnetic trip mechanisms

- Motor circuit protectors: Advanced features including adjustable trip settings, phase loss protection, and specialized motor protection

Protection Focus

- Circuit breakers: Protect general electrical circuits and wiring

- Motor circuit protectors: Specifically protect electric motors by monitoring current, temperature, and phase conditions

Application Areas

- Circuit breakers: Used in residential, commercial, and industrial electrical installations

- Motor circuit protectors: Exclusively designed for motor applications (industrial machinery, HVAC systems, production equipment)

Response Characteristics

- Circuit breakers: Standard trip curves for general overcurrent protection

- Motor circuit protectors: Specialized trip characteristics accounting for motor starting currents and running conditions

Reset and Operation

- Circuit breakers: Simple manual reset after tripping

- Motor circuit protectors: Include diagnostic features and specific reset procedures for safe motor restart

FAQs

Q1:Where can I use MPCB?

MPCBs are used in any application that requires motor protection, primarily in industrial and commercial equipment. Common applications include pumps, fans, compressors, conveyors, and manufacturing machinery.

Q2:How to size an MPCB?

Select an MPCB based on the motor’s full load current (FLC) and service factor (SF). The MPCB rating should be equal to or slightly higher than the motor’s FLC, while staying within the motor’s SF limits.

Q3:What is the range of MPCB?

Standard MPCBs typically cover current ranges from 0.1A to 100A, with voltage ratings up to 690V AC. The exact range varies by manufacturer and model series.

In Conclusion

Motor protection circuit breakers play a vital role in safeguarding electrical motors across various industrial applications. These devices combine overload protection, short-circuit protection, and phase monitoring in a single unit.

For optimal motor protection and system reliability, consult with a qualified electrical engineer to select and install the appropriate MPCB for your specific application.