A waterproof electrical box is a protective enclosure designed to shield electrical connections from moisture, dust, and extreme environmental conditions. These enclosures ensure safe and reliable operation in outdoor, industrial, and marine applications by preventing corrosion, short circuits, and equipment damage.

Key Features of Waterproof Electrical Boxes

1. IP & NEMA Ratings

Waterproof boxes are classified by Ingress Protection (IP) and NEMA ratings, which define their resistance to environmental factors:

| Protection Level | IP Rating | Application |

|---|---|---|

| Dustproof & water-resistant | IP65 | Outdoor lights, signage |

| Submersible (temporary) | IP67 | Underground cables, marine use |

| Submersible (prolonged) | IP68 | Pool systems, underwater equipment |

NEMA 4X-rated boxes (stainless steel or fiberglass) are ideal for corrosive environments like chemical plants.

2. Material Options

| Material | Pros | Cons |

|---|---|---|

| Polycarbonate | Lightweight, UV-resistant, affordable | Less impact-resistant than metal |

| Stainless Steel | Corrosion-proof, high durability | Higher cost |

| Aluminum | Lightweight, EMI shielding | Requires anti-corrosion coatings |

| Fiberglass | Extreme temperature resistance | Limited aesthetic options |

Why Choose a Waterproof Electrical Box?

Core Advantages

- Enhanced Safety: Prevents electrical shocks and fires by sealing out water and dust.

- Extended Lifespan: Reduces corrosion and wear on components, lowering maintenance costs.

- Compliance: Meets industry standards (e.g., NEC, UL) for outdoor and hazardous environments.

- Versatility: Used in solar panels, traffic systems, IoT devices, and industrial machinery.

Why Waterproof Electrical Boxes Matter

Key Applications

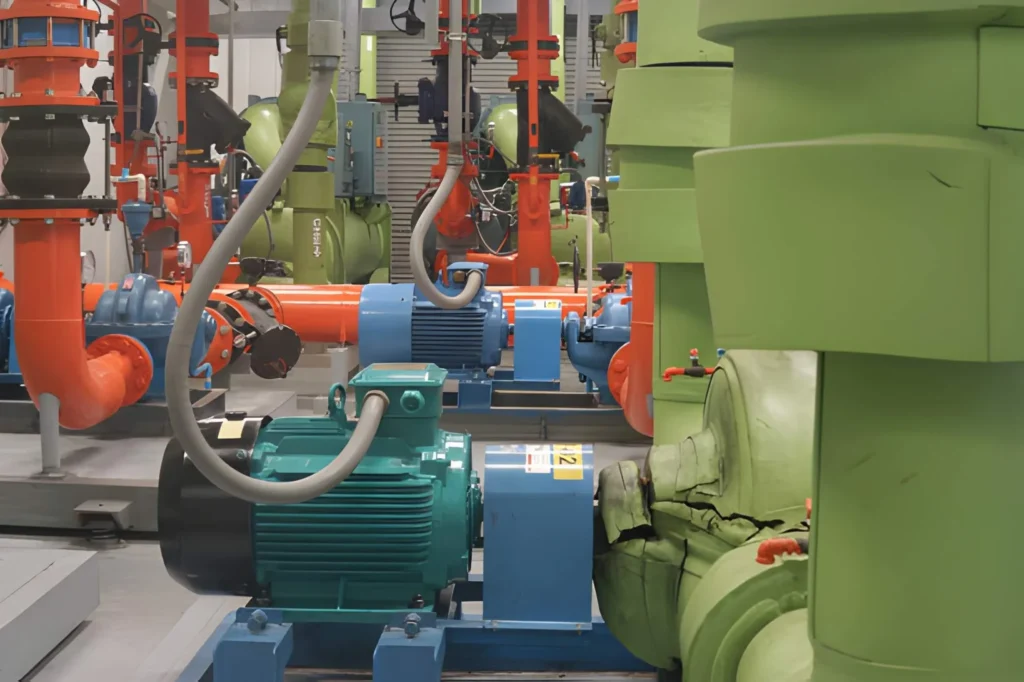

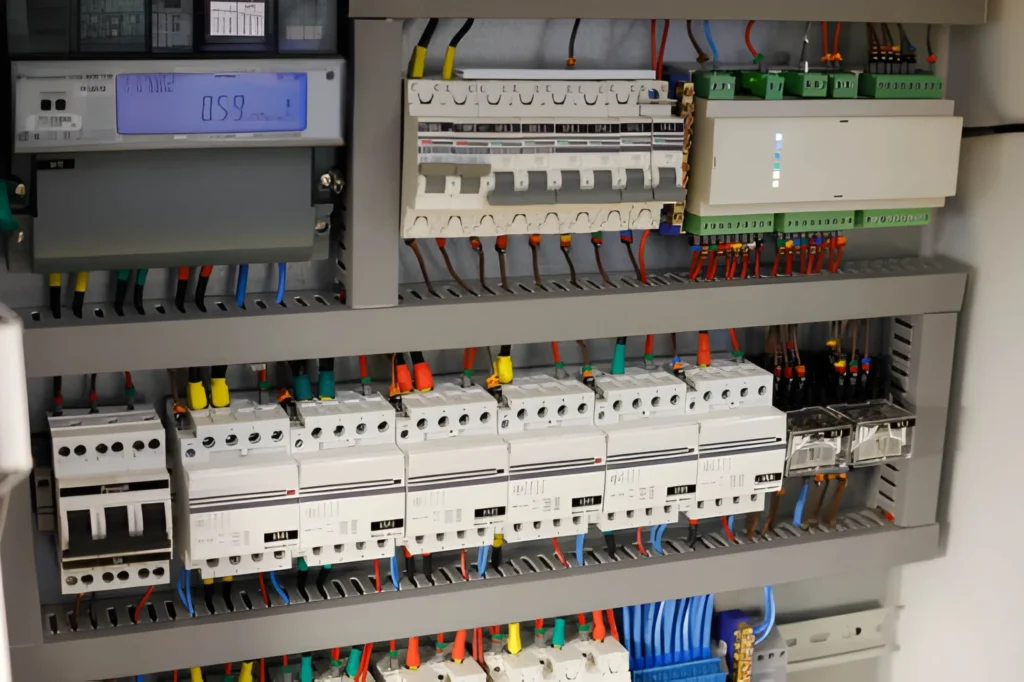

- Industrial Automation: Protects control panels in chemical plants (stainless steel boxes with NEMA 4X ratings).

- Renewable Energy: Safeguards solar inverters and wind turbine connections (UV-resistant polycarbonate).

- Smart Cities: Secures traffic light systems and EV charging stations (IP67-rated enclosures).

- Marine Engineering: Withstands saltwater corrosion in underwater sensors (IP68 fiberglass boxes).

How to Select the Right Waterproof Box

1.Assess Environmental Risks:

- For coastal areas, choose stainless steel (IP68).

- For UV-exposed sites, opt for UV-stabilized polycarbonate.

2.Match Electrical Load:

- High-voltage applications require metal boxes with grounding screws.

3.Prioritize Accessibility:

- Hinged lids or screw-sealed designs simplify maintenance.

Installation & Maintenance Best Practices

- Sealing Techniques: Use silicone gaskets and corrosion-resistant stainless steel hinges.

- Conduit Connections: Ensure all knockouts are properly fitted with waterproof conduit connectors.

- Surface Preparation: Apply powder coating for enhanced moisture resistance.

FAQs

Q: Can waterproof boxes be buried underground?

A: Yes, IP67/IP68-rated boxes are designed for underground use.

Q: Do plastic boxes rust?

A: No—polycarbonate and ABS are corrosion-proof, unlike uncoated metal.

Q: Are waterproof boxes fire-resistant?

A: Stainless steel and fiberglass models offer superior fire resistance.