Motor Circuit protection is a critical aspect of electrical system design. According to NFPA 70: National Electrical Code (NEC) Article 430, motor protection encompasses overload protection, short-circuit and ground-fault protection, conductors, control circuits, controllers, motor control centers, disconnecting means, adjustable-speed drive systems (such as variable frequency drives, or VFDs), and grounding. These guidelines are based on the 2017 edition of the NEC.

The Importance of Overload Protection

Part III of NEC Article 430 focuses on overload protection for motors and their circuits. It is essential to protect motors, motor control equipment, and branch circuit conductors from overloads and excessive heat. Additionally, ensuring that the motor can start and perform its intended function is equally important. Notably, Article 430 Part III does not apply to motor circuits rated above 1,000 volts. The focus here is on motors operating below 1,000 volts.

Overload vs. Overcurrent

Understanding the distinction between overload and overcurrent is crucial. Overcurrent occurs when the current exceeds the motor’s rated value or the ampacity of its conductors. This can result from an overload, short circuit, or ground fault. Overload refers specifically to prolonged operation beyond the motor’s full-load rating, which can lead to damage or overheating. However, short circuits or ground faults are not considered overload conditions, though overload is classified as a type of overcurrent.

Definitions and Protective Measures

- Short Circuit: An unintended electrical connection between two normally current-carrying conductors in a circuit (e.g., line-to-line or line-to-neutral).

- Ground Fault: An unintended conductive connection between an ungrounded conductor and non-current-carrying components such as metallic enclosures or the earth. During a ground fault, hazardous voltages may exist on metal parts until an overcurrent protection device (e.g., a fuse or circuit breaker) interrupts the circuit.

The NEC also specifies that motor overload protection is not required in cases where power loss could pose a life-safety hazard, such as with fire pumps.

Selecting Appropriate Overload Protection

The selection of an appropriate overload protection device depends on the motor’s full-load amperes (FLA), which is listed on the equipment nameplate. For continuous-duty motors with a service factor of 1.15 or higher or a temperature rise of 40°C as indicated on the nameplate, NEC 430.32 specifies that the overload device should not exceed 125% of the motor’s FLA.

Motor Circuit Protection Example Calculation

Consider a motor with:

- Service factor: 1.15

- FLA: 24.5 amperes

The overload device size would be calculated as follows:

24.5 amperes×1.25=30.625 amperes24.5 amperes×1.25=30.625 amperesThus, a 30-ampere overload protection device would be selected since it cannot exceed 125% of the FLA.

Short-Circuit and Ground-Fault Protection

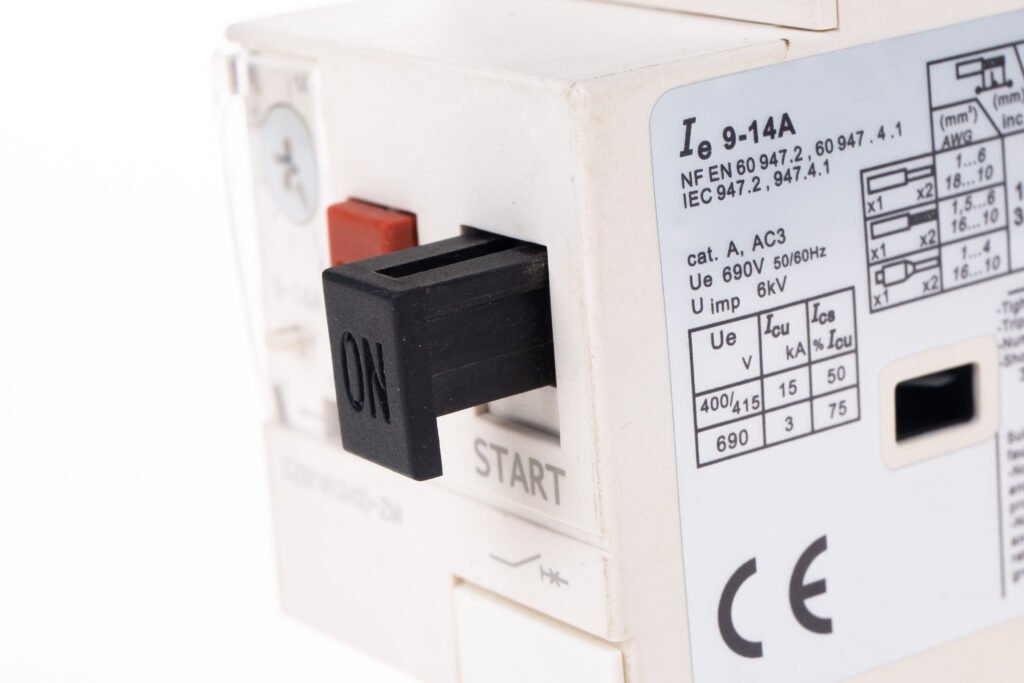

Part IV of NEC Article 430 outlines requirements for short-circuit and ground-fault protection for motors, including branch circuits, control equipment, and conductors. Article 430.52 requires that branch circuit short-circuit and ground-fault protective devices must accommodate the motor’s high inrush current during startup.

Example Calculation

To determine the inverse time circuit breaker size for a 5-horsepower, 230-volt single-phase motor:

- Refer to Table 430.52 under “Single-phase motors” in the “Inverse Time Breaker” column to find “250%.”

- If FLA data is unavailable during design, consult NEC Table 430.248 for typical values (e.g., FLA for a 5-horsepower motor at 230 volts = 28 amperes).

The calculation would then be:

28 amperes×2.50=70 amperes28 amperes×2.50=70 amperesA standard-sized 70-ampere circuit breaker would be selected as the maximum short-circuit and ground-fault protective device.

Lighting Systems as Continuous Loads

Lighting loads are classified by the NEC as continuous loads if their maximum current is expected to last three hours or more. According to NEC Article 210.19(A)(1)(a), branch circuit conductor sizes for continuous loads must be at least 125% of the load.

LED Lighting Considerations

LED lighting systems often experience high inrush currents upon startup, which can trip circuit breakers or blow fuses. To address this issue, slow-blow fuses or Type C/D breakers should be used.By designing circuits with appropriate protective devices and adhering to NEC guidelines, systems can operate safely and reliably while meeting code requirements. Special care must be taken when designing systems for life-safety applications such as elevators or smoke evacuation systems to ensure compliance with stringent safety standards.