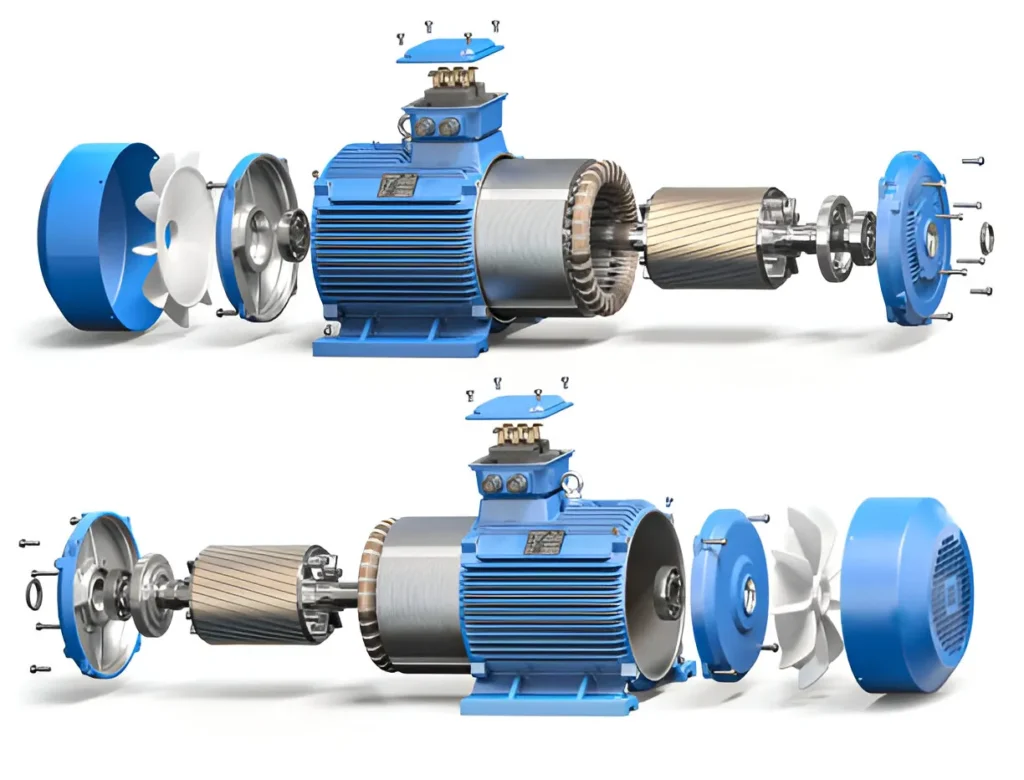

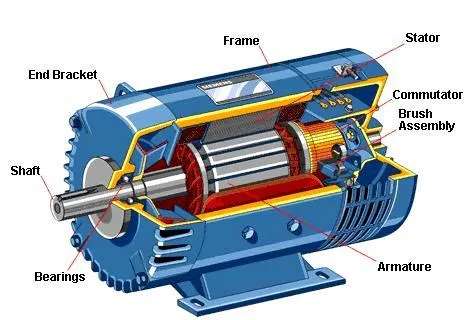

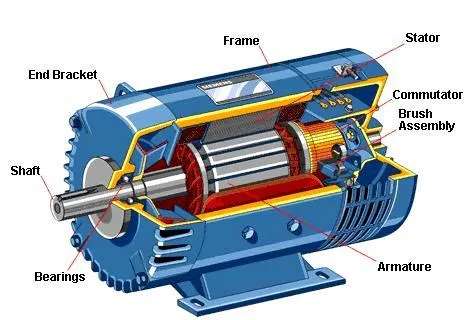

Motors are the core components of industrial and daily applications, and their stable operation is crucial for production efficiency and equipment longevity.

However, motors face various potential threats during operation, such as overloads, short circuits, phase loss, and mechanical failures.

These issues can not only damage the motor but also pose safety risks. Therefore, equipping motors with specialized protection devices is key to ensuring their efficient and safe operation.

Importance of Motor Protection

- Prevent Damage and Downtime

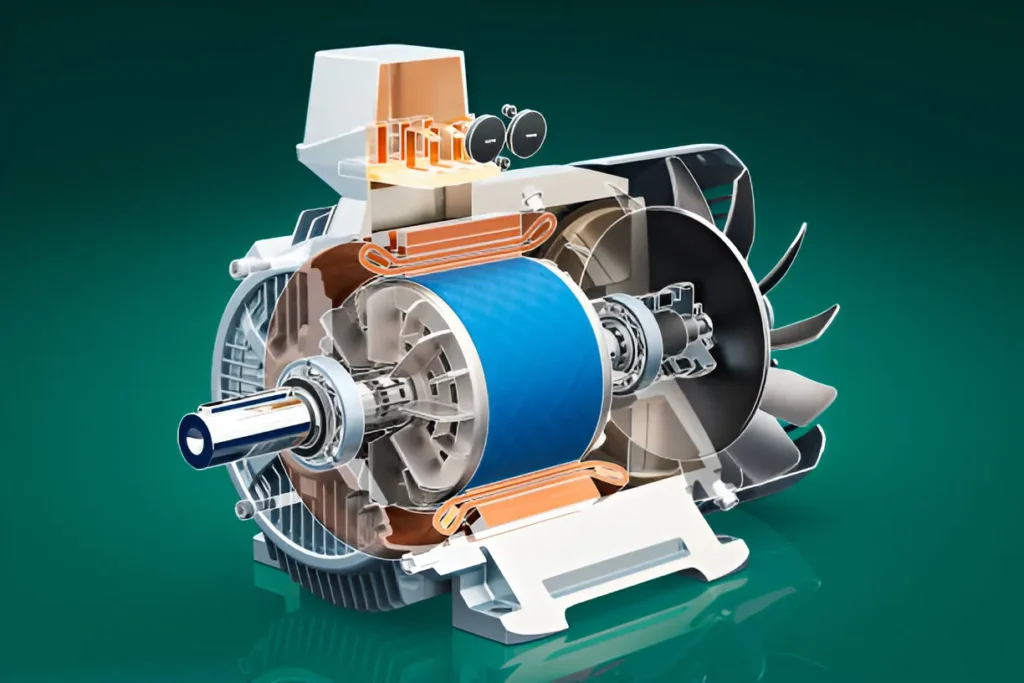

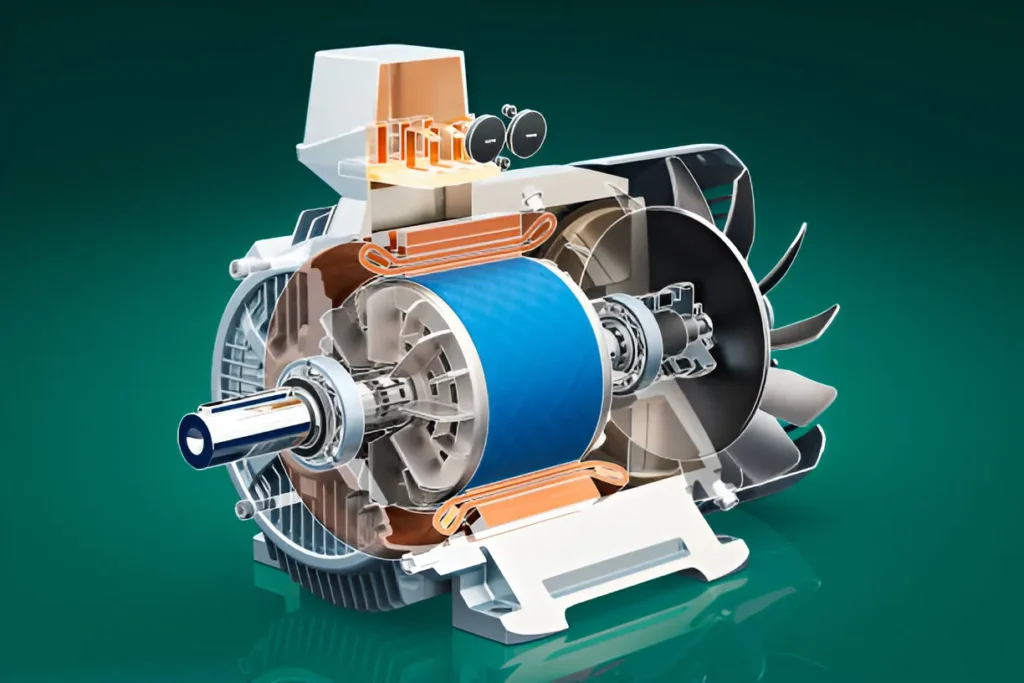

Motors operating under conditions like high temperatures, overloads, or electrical faults may suffer from burnt windings, damaged bearings, or even complete failure. Specialized protection devices can detect and isolate faults in time to prevent further damage. - Extend Equipment Lifespan

Protection devices reduce wear and tear caused by frequent faults, thereby prolonging the service life of motors and related equipment. - Improve Production Efficiency

By minimizing unplanned downtime, protection devices ensure continuous production line operation, boosting overall efficiency.

Common Motor Faults and Their Risks

Overload

- Phenomenon: Current exceeds the rated value, causing excessive heat in the windings.

- Risk: Insulation degradation or burnout; in severe cases, it may lead to fires.

Short Circuit

- Phenomenon: A sudden surge in current flow.

- Risk: Melting cables, burnt windings, and potential damage to surrounding equipment.

Phase Loss or Imbalance

- Phenomenon: One phase of a three-phase power supply is disconnected or unbalanced.

- Risk: Reduced torque, overheating of windings, and potential burnout.

Mechanical Issues

- Problems such as bearing failure, vibration, or misalignment can accelerate component wear and reduce efficiency.

Main Methods for Motor Protection

Thermal Relays

Detect temperature changes to provide overload protection but offer limited functionality.

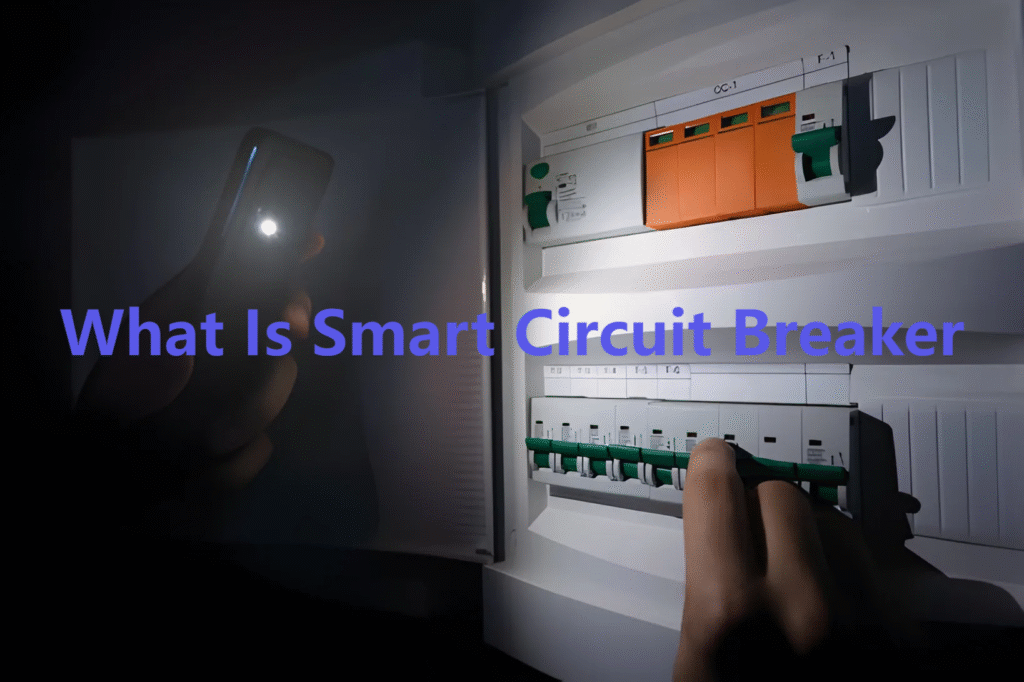

Motor Protection Circuit Breakers (MPCB)

Combine thermal and magnetic protection functions to address overloads, short circuits, phase loss, and more. They feature real-time monitoring and quick response capabilities, making them ideal for industrial applications.

Intelligent Protection Devices

Utilize microprocessor technology for real-time data monitoring, remote operation, and predictive maintenance to enhance system intelligence.

Advantages of Motor Protection Circuit Breakers (MPCB)

Multi-Function Integrated Design

- Combines the functionalities of thermal relays and circuit breakers to save space and simplify installation processes.

High Sensitivity and Quick Response

- Detects abnormalities rapidly and cuts off power to prevent further damage.

Wide Range of Applications

- Suitable for various industrial equipment such as pumps, fans, compressors, and conveyors—especially in high-load or continuous operation scenarios.

Supports Intelligent Management

- Advanced MPCBs offer remote monitoring and diagnostic features that help optimize maintenance schedules and improve energy efficiency.

Necessity of Specialized Motor Protection

Ensure Safety

- Reduces risks of personal injury or equipment damage caused by faults.

Lower Operational Costs

- Minimizes repair frequency and downtime while maximizing return on investment.

Support Sustainability Goals

- Optimizes energy consumption, reduces carbon emissions, and promotes green production.

Conclusion

To ensure the safe and efficient operation of motors, it is essential to choose appropriate protection devices such as MPCBs or intelligent protection systems based on specific requirements. Regular maintenance and inspections are also critical aspects that should not be overlooked.

By implementing scientific motor protection measures, you can not only extend equipment lifespan but also significantly enhance production efficiency while reducing operational costs.

FAQs

1.What is a Motor Protection Circuit Breaker (MPCB)?

An MPCB is a device designed to protect motors from faults such as overloads, short circuits, and phase imbalances. It combines thermal and magnetic protection functions, offering quick response and real-time monitoring to prevent motor damage.

2.How does an MPCB differ from a standard circuit breaker?

Unlike standard circuit breakers, MPCBs are specifically designed for motor applications. They provide tailored protection against motor-specific issues like overloads and phase loss, while also offering features like adjustable trip settings and higher sensitivity.

3.What types of equipment can an MPCB protect?

MPCBs are suitable for a wide range of equipment, including pumps, fans, compressors, conveyors, and other industrial machinery that rely on motors.